1. Introduction

2. The EMULF project and the 15MW semi-submersible wind turbine

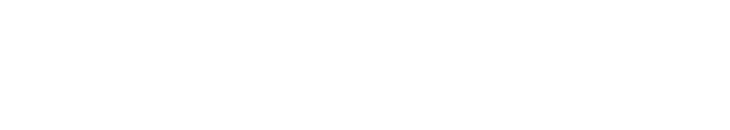

Fig. 1. Illustration of the UMaine semi-submersible with the IEA 15MW wind turbine ([14], left: overview; right: bird view). |

Table 1. Main features of the IEA 15MW wind turbine [20]. |

| Parameter | Value | Unit |

|---|---|---|

| Rated power | 15 | MW |

| Control | Variable speed, collective pitch | |

| Cut-in, rated, cut-out wind speed | 3, 10.59, 25 | m/s |

| Minimum, maximum rotor speed | 5, 7.56 | rpm |

| Rotor diameter | 240 | m |

| Hub height | 150 | m |

| Blade mass | 65 | ton |

| Rotor nacelle assembly mass | 1017 | ton |

| Tower mass | 860 | ton |

Table 2. Main dimensions of the UMaine semi-submersible [21]. |

| Parameter | Value | Unit |

|---|---|---|

| Displacement | 20,711 | ton |

| Floater steel mass | 3914 | ton |

| Draft | 20 | m |

| Side column freeboard | 15 | m |

| Central column diameter | 10 | m |

| Side column diameter, length | 12.5, 35 | m |

| Distance between central and side column centres | 51.75 | m |

| Pontoon height, width | 12.5, 7 | m |

| Vertical position of CoG from SWL | −14.94 | m |

| Vertical position of CoB from SWL | −13.63 | m |

| Water depth | 200 | m |

| Mooring system | Three catenary chain lines | |

| Surge natural period | 143 | s |

| Sway natural period | 143 | s |

| Heave natural period | 20.4 | s |

| Roll natural period | 27.8 | s |

| Pitch natural period | 27.8 | s |

| Yaw natural period | 90.1 | s |

| 1st tower bending natural period (fore-aft) | 2.02 | s |

| 1st tower bending natural period (side-to-side) | 2.07 | s |

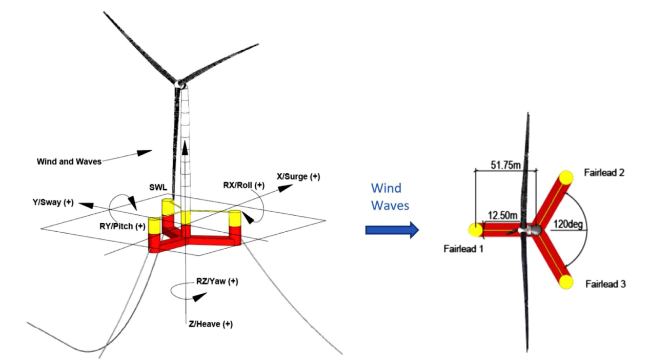

3. General methodology for floater stress analysis

Fig. 2. Analysis procedure for reconstruction of the applied loads for floater stress analysis (left: the global model in SIMA; middle: the panel model in WADAM or WASIM; right: the finite element model in SESTRA). |

Table 3. Relationship between wave elevation and floater motion as input and the corresponding wave pressure as output. |

| Input | Output | Relationship |

|---|---|---|

| General input u(t) | General output y(t) | Transfer function HUY(ω) |

| Wave elevation at the reference point ζ(t) | Wave excitation pressure at panel j pje(t) | Transfer function HZPEj(ω) |

| Floater motion in DOF i xi(t) | Wave radiation pressure at panel j (added mass and potential damping terms) pjir(t) | Transfer function HXiPRj(ω) |

| Floater motion in DOF i xi(t) | Time-varying hydrostatic pressure at panel j pjis(t) | Transfer function HXiPSj(ω) |

4. Analysis procedure in the DNV software package

5. Case study for verification - wave-induced floater stress analysis

5.1. General

Table 4. Defined wave conditions. |

| Case No. | Hs (m) | Tp (s) | Wave direction (deg) |

|---|---|---|---|

| Case 1 | 1.84 | 7.44 | 0 |

| Case 2 | 4.52 | 9.45 | 0 |

| Case 3 | 10.7 | 14.2 | 0 |

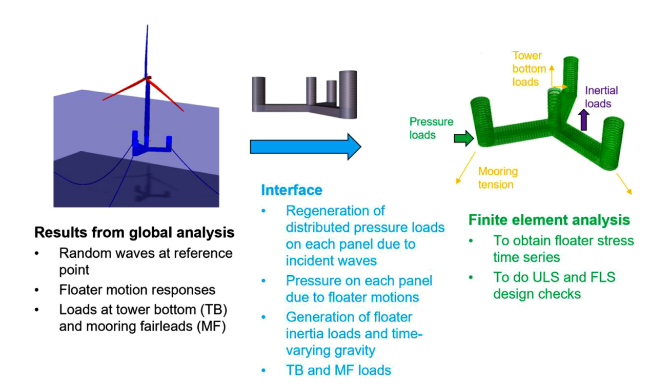

5.2. Definition of the positions for hydrodynamic pressure output and floater stress calculation

Fig. 3. Definition of the positions for hydrodynamic pressure (blue star) and stress (black circle) comparison (left: birdview; right: sideview). |

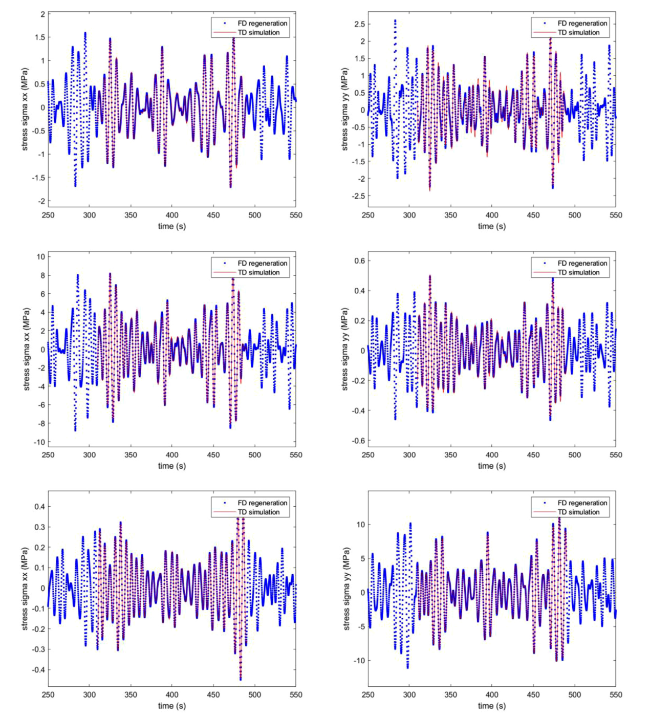

Fig. 5. Comparison of the stress times series for Case 1 by the frequency-domain regeneration (FD) and the time-domain direct analysis (TD) for the positions of FC1 (upper), FP1 (middle) and CC1 (bottom). |

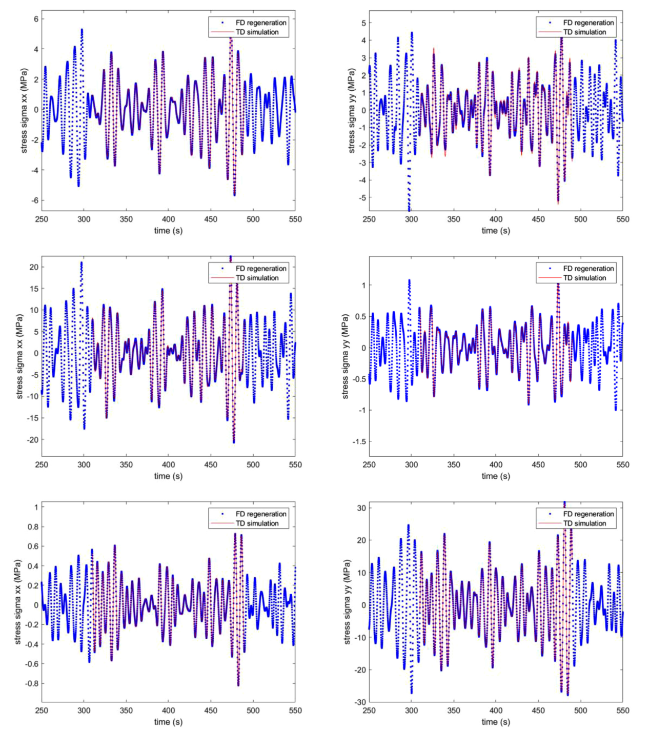

Fig. 6. Comparison of the stress times series for Case 2 by the frequency-domain regeneration (FD) and the time-domain direct analysis (TD) for the positions of FC1 (upper), FP1 (middle) and CC1 (bottom). |

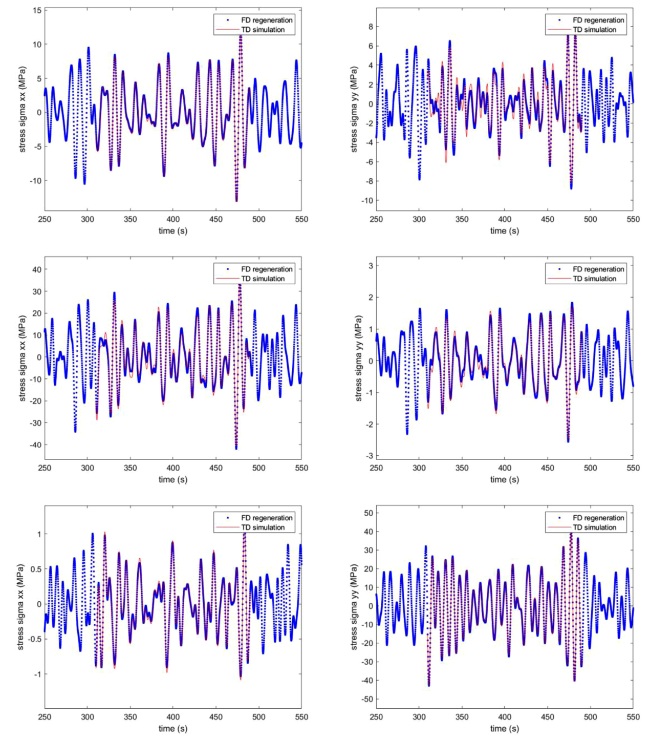

Fig. 7. Comparison of the stress times series for Case 3 by the frequency-domain regeneration (FD) and the time-domain direct analysis (TD) for the positions of FC1 (upper), FP1 (middle) and CC1 (bottom). |

Table 5. Comparison of the stress standard deviation for Case 1. |

| Case 1 | FC1 | FC2 | FP1 | FP2 | CC1 | CC2 | SC1 | SC2 | SP1 | SP2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sigma_XX std | FD (MPa) | 0.56 | 0.42 | 3.01 | 2.12 | 0.14 | 0.75 | 0.25 | 0.12 | 1.34 | 0.28 |

| TD (MPa) | 0.56 | 0.41 | 2.99 | 2.10 | 0.14 | 0.74 | 0.25 | 0.12 | 1.34 | 0.29 | |

| Difference in % | −0.44% | −1.86% | −0.73% | −0.81% | −1.99% | −1.04% | −0.11% | −1.07% | −0.67% | 1.37% | |

| Sigma_YY std | FD (MPa) | 0.75 | 1.39 | 0.17 | 0.07 | 3.91 | 4.38 | 0.30 | 0.78 | 0.64 | 0.85 |

| TD (MPa) | 0.76 | 1.42 | 0.17 | 0.07 | 3.84 | 4.34 | 0.30 | 0.78 | 0.64 | 0.83 | |

| Difference in % | 1.77% | 2.19% | 0.43% | −3.76% | −1.67% | −1.02% | 2.61% | −0.57% | −0.11% | −2.12% |

Table 6. Comparison of the stress standard deviation for Case 2. |

| Case 2 | FC1 | FC2 | FP1 | FP2 | CC1 | CC2 | SC1 | SC2 | SP1 | SP2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sigma_XX std | FD (MPa) | 1.95 | 1.19 | 6.67 | 4.20 | 0.26 | 1.93 | 0.74 | 0.38 | 2.61 | 0.47 |

| TD (MPa) | 1.93 | 1.19 | 6.54 | 4.11 | 0.26 | 1.91 | 0.74 | 0.38 | 2.62 | 0.48 | |

| Difference in % | −1.10% | −0.66% | −1.88% | −2.13% | −0.52% | −1.01% | −0.35% | −0.50% | 0.47% | 1.57% | |

| Sigma_YY std | FD (MPa) | 1.54 | 3.03 | 0.34 | 0.16 | 10.14 | 11.35 | 0.51 | 1.39 | 1.52 | 1.40 |

| TD (MPa) | 1.56 | 3.04 | 0.34 | 0.16 | 9.97 | 11.24 | 0.52 | 1.40 | 1.51 | 1.40 | |

| Difference in % | 1.18% | 0.43% | −1.48% | −0.05% | −1.63% | −1.01% | 2.08% | 0.19% | −0.44% | −0.06% |

Table 7. Comparison of the stress standard deviation for Case 3. |

| Case 3 | FC1 | FC2 | FP1 | FP2 | CC1 | CC2 | SC1 | SC2 | SP1 | SP2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sigma_XX std | FD (MPa) | 4.40 | 3.01 | 12.99 | 8.21 | 0.41 | 3.03 | 2.02 | 1.05 | 4.04 | 1.07 |

| TD (MPa) | 4.36 | 3.01 | 12.79 | 8.08 | 0.43 | 3.00 | 2.04 | 1.07 | 4.03 | 1.20 | |

| Difference in % | −0.77% | 0.04% | −1.56% | −1.56% | 4.01% | −1.06% | 1.05% | 1.58% | −0.18% | 12.54% | |

| Sigma_YY std | FD (MPa) | 2.62 | 5.21 | 0.81 | 0.26 | 15.92 | 17.65 | 0.98 | 2.03 | 2.76 | 2.19 |

| TD (MPa) | 2.56 | 5.21 | 0.80 | 0.27 | 15.68 | 17.46 | 0.73 | 2.02 | 3.08 | 2.33 | |

| Difference in % | −2.34% | 0.05% | −1.23% | 2.70% | −1.51% | −1.05% | −24.79% | −0.57% | 11.40% | 6.45% |

5.3. Comparison of the hydrodynamic pressure components of the floater

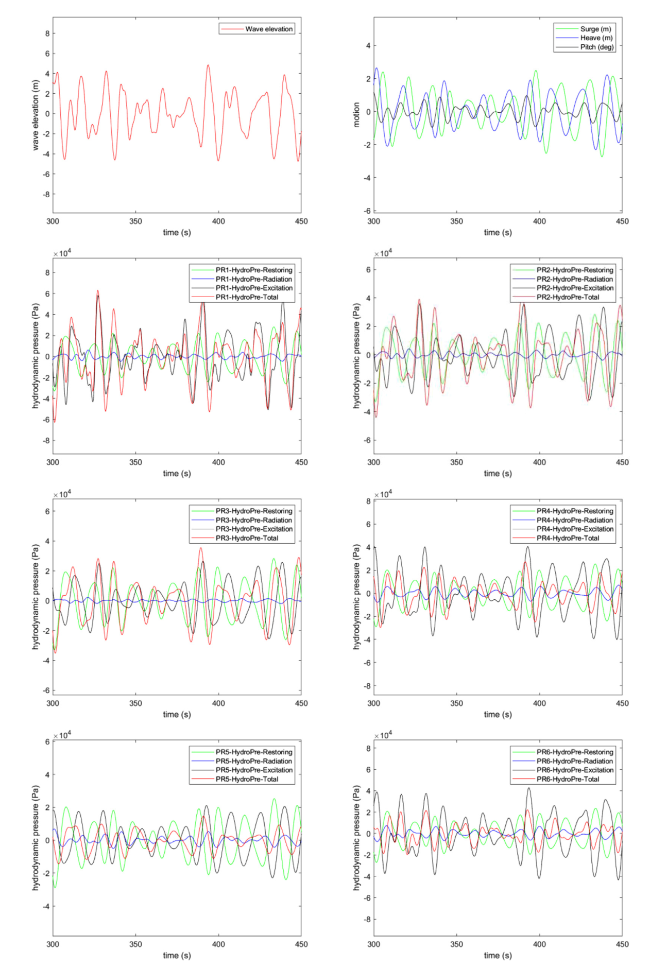

Fig. 4. Comparison of the times series for Case 3 of the wave elevation, the floater motions, the hydrodynamic pressure components at the positions of PR1-PR6. |