1. Introduction

2. Model description

2.1. Physical model

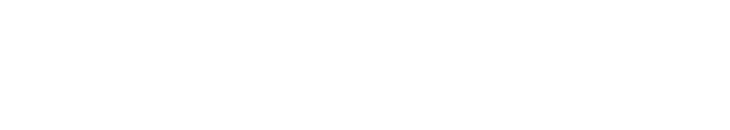

Fig. 1. Schematic of the investigated fin designs: (a) concentric circular fin; (b) eccentric circular fin; (c) perforated circular fin; (d) serrated circular fin; (e) star-shaped fin; (f) front view of the star-shaped fin. |

Table 1. Geometry of the finned-tubes (all dimensions are in mm). |

| Fin type | Tube diameterDt | Fin diameterDf | Fin spacingS | Fin thicknesstf | Transversetube pitchPt | Longitudinal tube pitchPl | Segment widthws | Segmentheighths | PerforateddiameterDp | TubeshiftSt |

|---|---|---|---|---|---|---|---|---|---|---|

| CCFT | 20 | 40 | 2-7 | 0.5 | 50 | 40 | ||||

| ECFT | 20 | 40 | 2-7 | 0.5 | 50 | 40 | 3.8 | |||

| PCFT | 20 | 40 | 2-7 | 0.5 | 50 | 40 | 4 | |||

| SCFT | 20 | 40 | 2-7 | 0.5 | 50 | 40 | 3.97 | 6.5 | ||

| S-SFT | 20 | 40 | 2-7 | 0.5 | 50 | 40 | 6.5 |

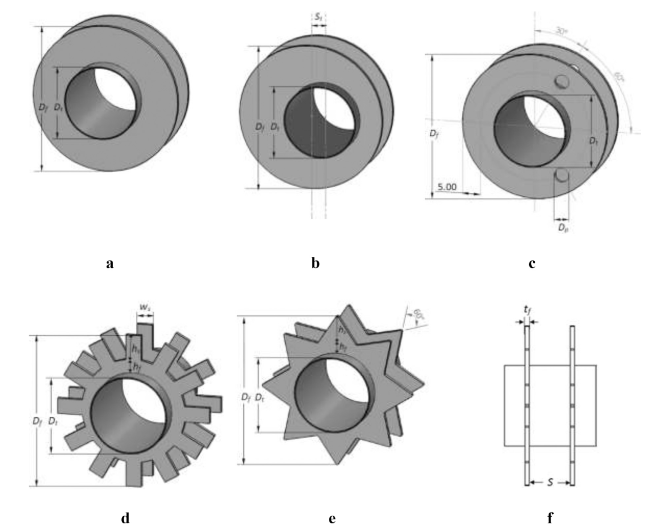

Fig. 2. Computational domain: (a) Geometry with the boundary conditions adopted; (b) A view from the top of the computational domain. |

2.2. Materials and methods

2.2.1. Governing equations

2.2.2. Boundary conditions

2.3. Numerical prediction

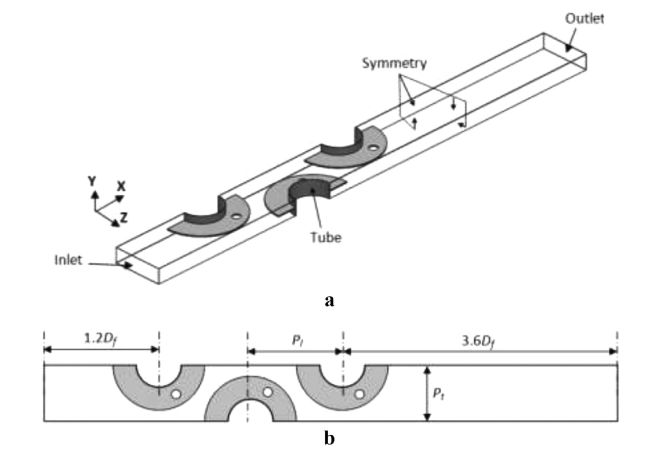

Fig. 3. Grid generations for: (a) concentric circular fin; (b) eccentric circular fin; (c) perforated circular fin; (d) serrated circular fin; (e) star-shaped fin. |

Table 2. Results of the grid independence tests. |

| Fin type | Star-shaped fin | Perforated fin | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of cells | 1.2 × 106 | 1.9 × 106 | 2.6 × 106 | 3.4 × 106 | 4.4 × 106 | 1.2 × 106 | 1.9 × 106 | 2.6 × 106 | 3.4 × 106 | 4.4 × 106 | |

| j | S = 2 mm | 0.0091 | 0.0082 | 0.0078 | 0.0078 | 0.0078 | 0.008 | 0.0076 | 0.0073 | 0.0073 | 0.0072 |

| S = 7 mm | 0.011 | 0.0101 | 0.0094 | 0.0089 | 0.0089 | 0.0097 | 0.009 | 0.0084 | 0.0079 | 0.0078 | |

| f | S = 2 mm | 0.3223 | 0.278 | 0.2466 | 0.2396 | 0.2365 | 0.2801 | 0.2594 | 0.2402 | 0.2371 | 0.2347 |

| S = 7 mm | 0.1435 | 0.1105 | 0.0992 | 0.0878 | 0.0871 | 0.1245 | 0.103 | 0.0946 | 0.087 | 0.0861 | |

2.4. Data reduction

3. Validation of the numerical model

Table 3. Validation of the numerical results for perforated, serrated, and star-shaped fins. |

| Perforated fin | Serrated fin | Star-shaped fin | ||||||

|---|---|---|---|---|---|---|---|---|

| uin(m/s) | h(W/m2K) [16] | h(W/m2K)(Present work) | ${{\operatorname{Re}}_{{{D}_{t}}}}$ | j/f [52] | j/f(Present work) | uin(m/s) | Nu [26] | Nu(Present work) |

| 4 | 81.01 | 79.32 | 7500 | 105.4 | 106.08 | 1.7 | 37.1 | 37.85 |

| 13,500 | 102.2 | 104.6 | 3.7 | 69.1 | 72.32 | |||

| 20,000 | 97.4 | 101.32 | 5.9 | 81.7 | 85.37 | |||

4. Results and analysis

4. 1. Flow characteristics

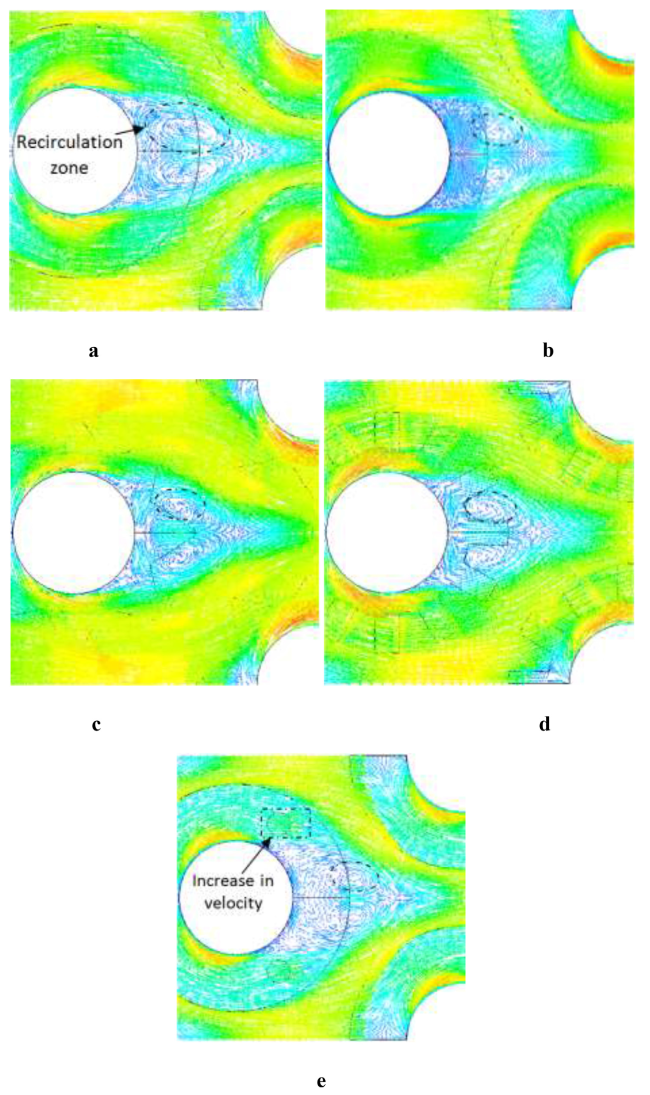

Fig. 4. Velocity vectors for: (a) Concentric circular fin; (b) Eccentric circular fin; (c) Star-shaped fin; (d) Serrated circular fin; (e) Perforated circular fin. |

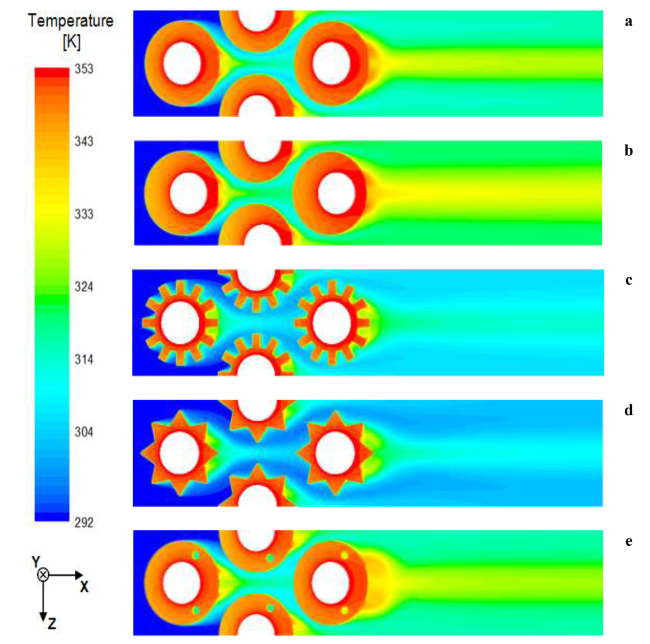

Fig. 5. Temperature contours in the middle of the fin thickness: (a) Concentric circular fin; (b) Eccentric circular fin; (c) Star-shaped fin; (d) Serrated circular fin; (e) Perforated circular fin. |

4.2. Influence of the fin design

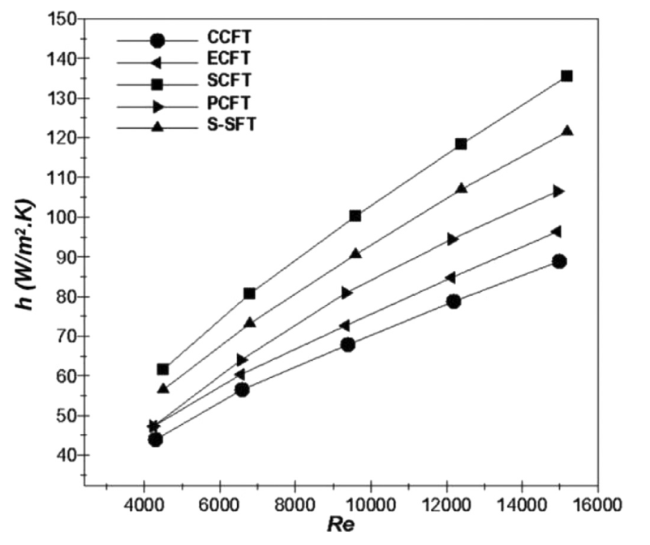

Fig. 6. Effect of the fin design on heat transfer coefficient at different Reynolds numbers. |

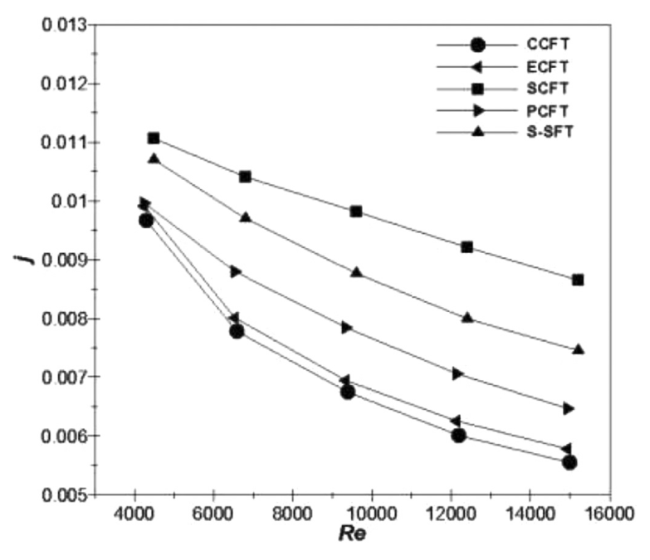

Fig. 7. Effect of the fin design on Colburn factor at different Reynolds numbers. |

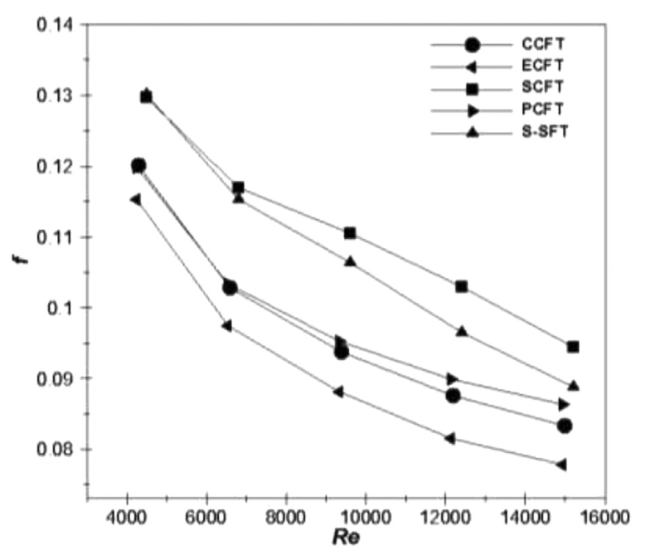

Fig. 8. Effect of fin design on friction factor at different Reynolds numbers. |

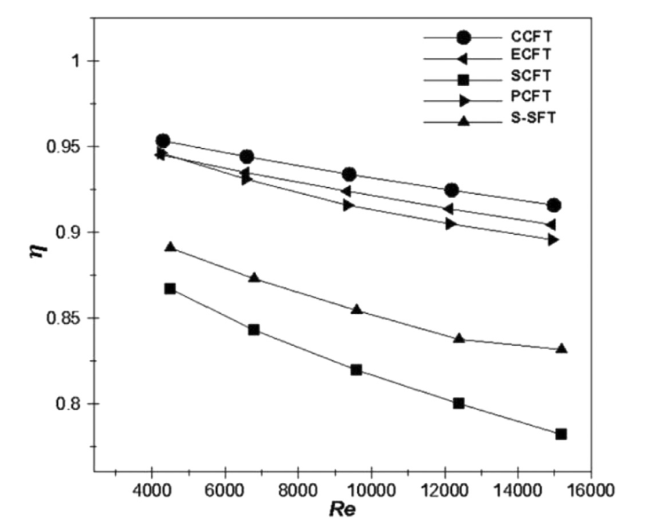

Fig. 9. Effect of the fin design on its efficiency at different Reynolds numbers. |

4.3. Impact of the fin spacing

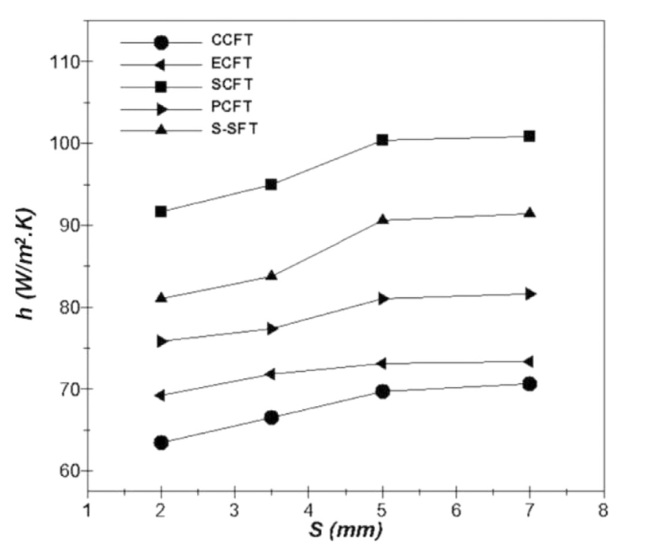

Fig. 10. Influence of the fin spacing on heat transfer coefficient, at uin = 3.7 m/s. |

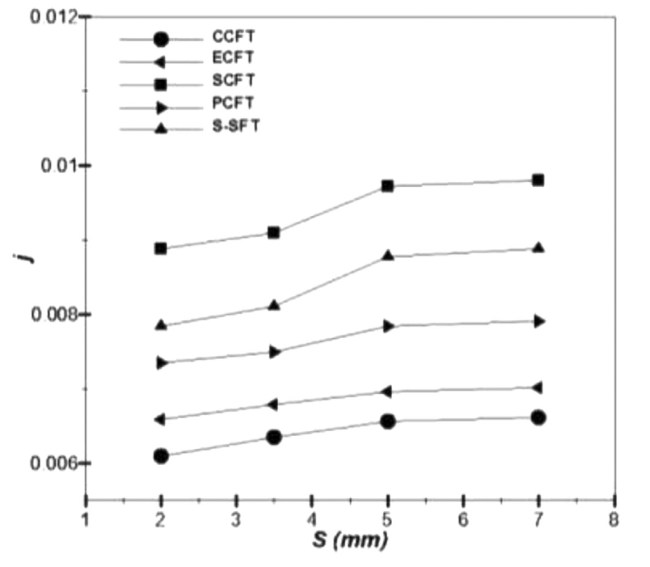

Fig. 11. Influence of the fin spacing on Colburn factor, at uin = 3.7 m/s. |

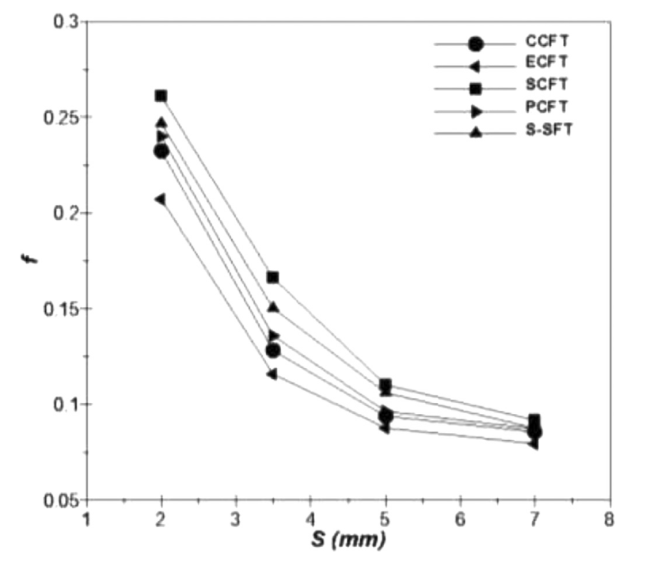

Fig. 12. Influence of the fin spacing on the friction factor, at uin = 3.7 m/s. |

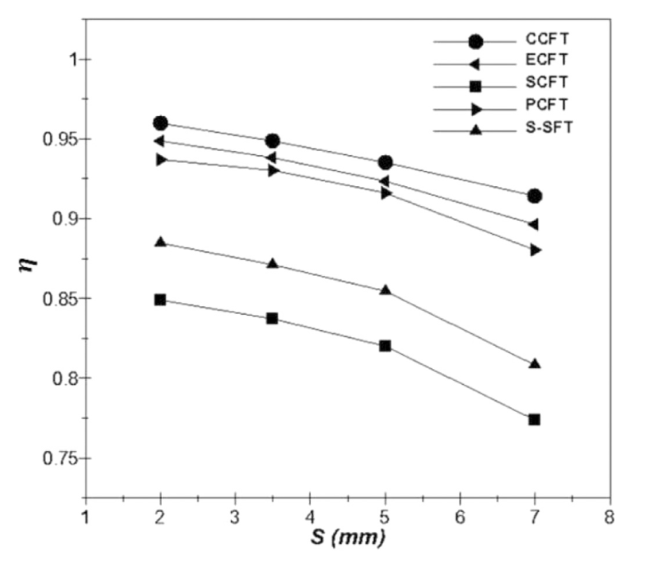

Fig. 13. Influence of the fin spacing on the fin efficiency, at uin = 3.7 m/s. |

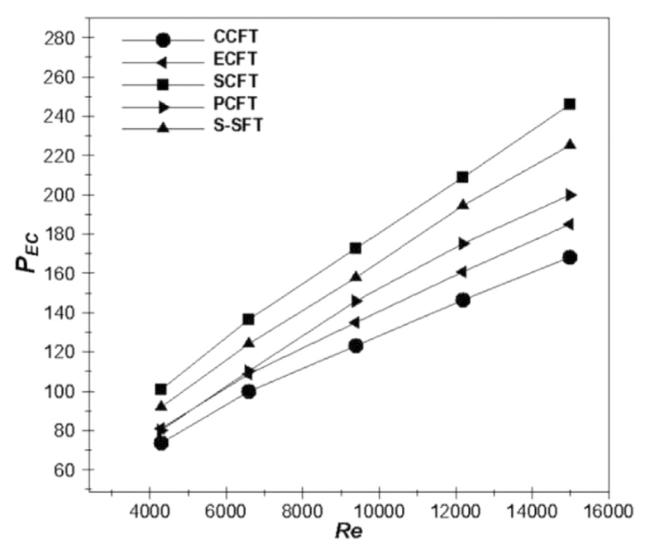

Fig. 14. Influence of the fin shape and Reynolds number on the performance evaluation criterion, at S = 5 mm. |

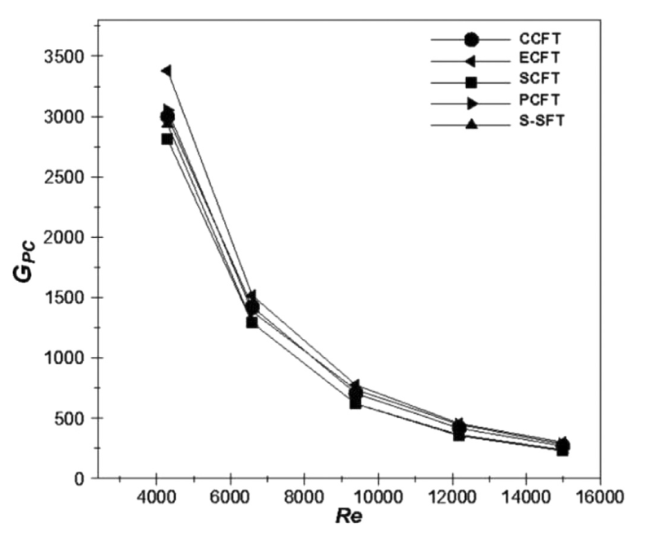

Fig. 15. Influence of the fin shape and Reynolds number on the global performance criterion, at S = 5 mm. |

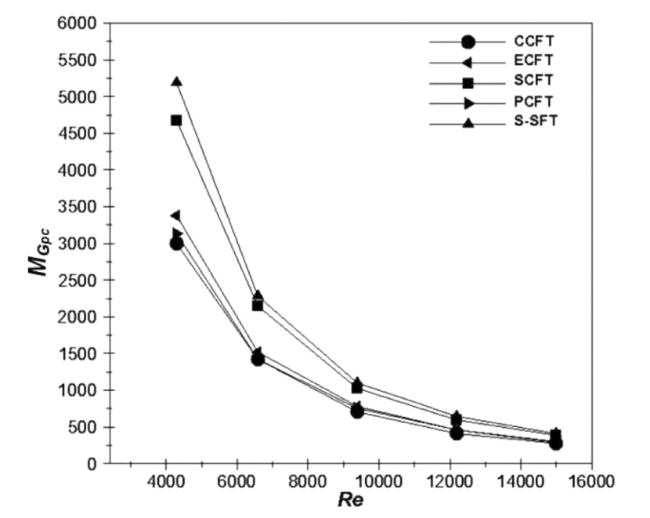

Fig. 16. Influence of the fin shape and Reynolds number on the mass global performance criterion, at S = 5 mm. |