HIGHLIGHTS

1 Introduction

2 Experimental Section

2.1 Materials

2.2 Preparation of Triboelectric Gels

2.3 Characterization

2.4 Mechanical and Rheological Testing

2.5 Thermodynamic Analysis and Environmental Stability

2.6 Cytotoxicity and Antimicrobial Properties Testing

2.7 Electrical and Sensing Testing

3 Results and Discussion

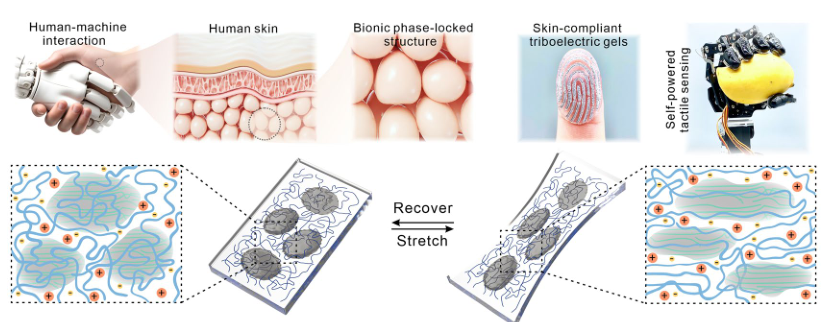

3.1 Design Principle of Bioinspired Compliant Iontronic Triboelectric Gels

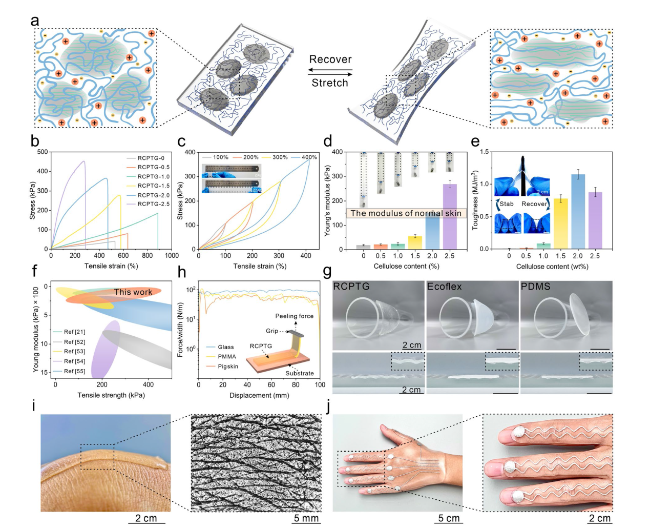

Fig. 1 Design principle of bioinspired compliant triboelectric gels. a Natural phase-locked structures in human subcutaneous tissue. b Process of inducing phase separation via solvent-unsolvent effects to construct phase-locked structures. c Compliant contact of RCPTG with human skin without any adhesive. d Properties of RCPTG compared to reported elastic triboelectric materials, including flexibility, stretchability, toughness, triboelectric responsivity, adhesion, and transparency. e RCPTG-based on-skin device is loaded on the small arm of the human body |

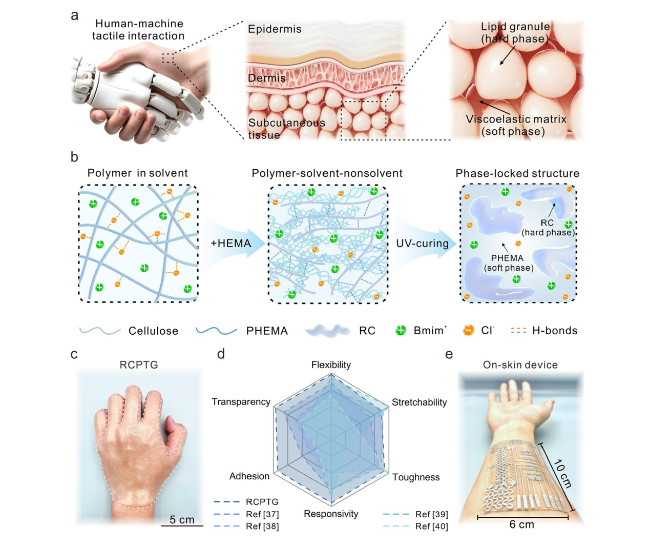

3.2 Phase-Locked Feature Enabled by Competitive Hydrogen Bonding Induced Phase Separation

Fig. 2 Phase separation induced by hydrogen bonding competition strategy. a Schematic diagram of a rigid-flexible network with phase separation features. b Process of inducing phase separation through solvent-nonsolvent effects. c Snapshots of MD in cellulose regeneration processes. d XRD spectra of gels with different HEMA contents. e 2D WAXS patterns of gels with different cellulose contents. f CLSM images show areas of increasing degree of phase separation, with the bright portion being the RC after staining, scale: 200 μm |

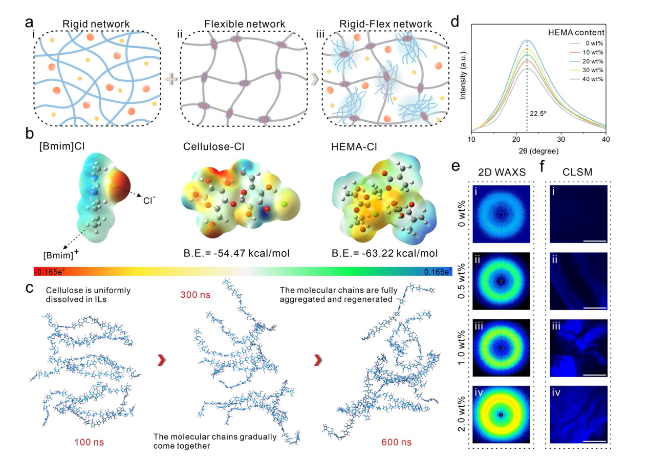

3.3 Rheology and Environmental Stability of Iontronic Triboelectric Gels with Phase-Locked Structures

Fig. 3 Effect of phase separation on rheological and environmental stability of triboelectric gels. a Preparation process of RCPTG with phase-locked structure. b Computed tomography reconstruction of phase-locked structures in RCPTG by nano-CT. c AFM phase diagram of RCPTGs. d The linear viscoelastic region of RCPTGs. e Frequency loss factors for RCPTGs. f TGA analysis of RCPTGs. g Moisture absorption and environmental stability of RCPTGs |

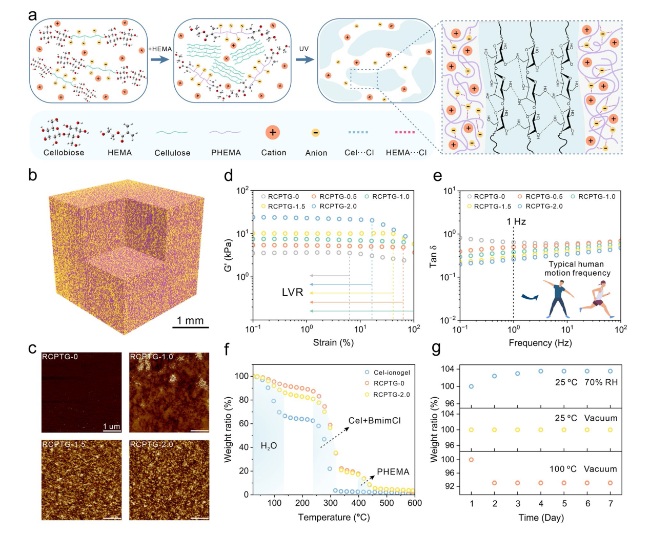

3.4 Compliant Mechanical Properties Endowed by Phase-Locked Structure

Fig. 4 Skin-like compliant mechanical properties enabled by phase separation strategy. a Interphase load transfer mechanism in phase-locked structure of RCPTG. b Tensile stress-strain curve. c Stretching cycle curves, insets show the original state and the RCPTG stretched to 400%, respectively. d Young’s modulus of RCPTGs, where the Young’s modulus of RCPTG-2.0 is within the modulus interval of human skin tissue. Inset: RCPTGs suspended with 100 g weights. e Comparison of toughness of RCPTGs. Inset: puncture resistance of RCPTG. f Comparison of modulus and strength of RCPTG with reported elastic materials. g Comparison of RCPTG with commercial gels (Ecoflex, PDMS). h Peel strength of RCPTG with glass, PMMA, and pigskin, respectively. i RCPTG forms a favorable conformal contact with human epidermal wrinkles. j RCPTG-skin with flexible circuitry and its detailed view |

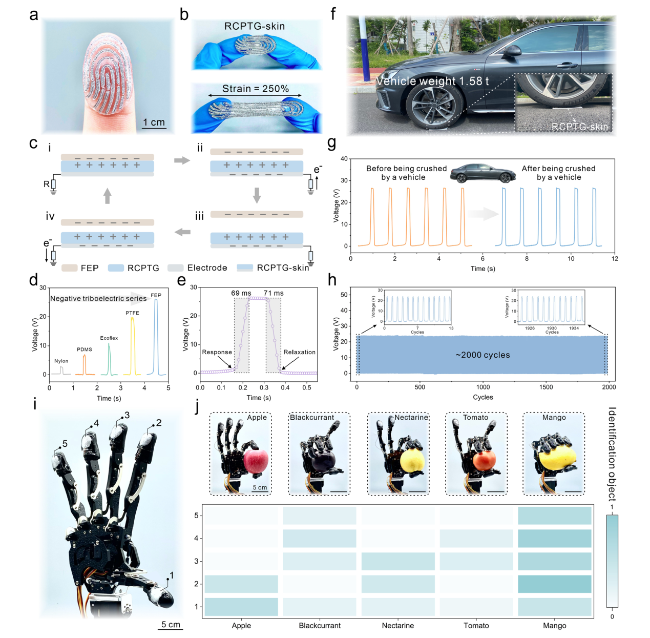

3.5 Wearable Self-Powered Tactile Sensing based on Compliant Iontronic Triboelectric Gels

Fig. 5 Self-powered perception properties of triboelectric tactile skin. a Compliant RCPTG-skin configured on a finger. b Images of RCPTG-skin before (top) and after (bottom) being stretched. c Self-powered sensing mechanism of RCPTG-skin based single-electrode triboelectric nanogenerator. d Contact electrification properties of RCPTG-skin paired with different commercial materials. e Self-powered response and relaxation time of RCPTG-skin. f Image of RCPTG-skin when subjected to destructive crushing by a vehicle weighing 1.58 t. g Comparison of the triboelectric output of RCPTG-skin before and after crush. h Sensing stability of RCPTG-skin at ~ 2000 cycles. i Image of a triboelectric tactile sensory system. j A robotic hand integrated with self-powered tactile skin serves as an operable haptic gripper that recognizes grasping motions and strengths based on the magnitude of triboelectric signals |