1 Introduction

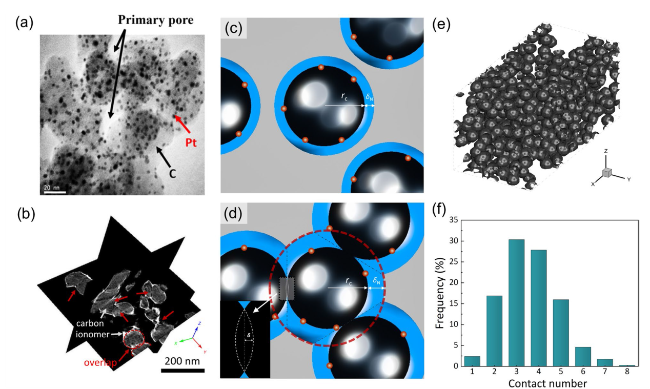

Fig. 1 Structure characterization of the CLs. (a) TEM image where Pt particles, carbon particles and primary pores are resolved. (b) Three ortho slices extracted from the tomograms of a catalyst layer sample (I/C=0.5) (modified from Ref. [12]). (c) Carbon particles without contact and overlap corresponding to the state-of-art single-particle model widely adopted in the literature. (d) Carbon particles with contact and overlap. (e) The reconstructed CL structures with carbon particles by adopting the reconstruction method in Ref. [13]. (f) Frequency distribution of contact number k |

2 Development of carbon particle-overlapping model

2.1 Characterization of the carbon particle overlapping

2.2 Structural model for carbon particle overlapping

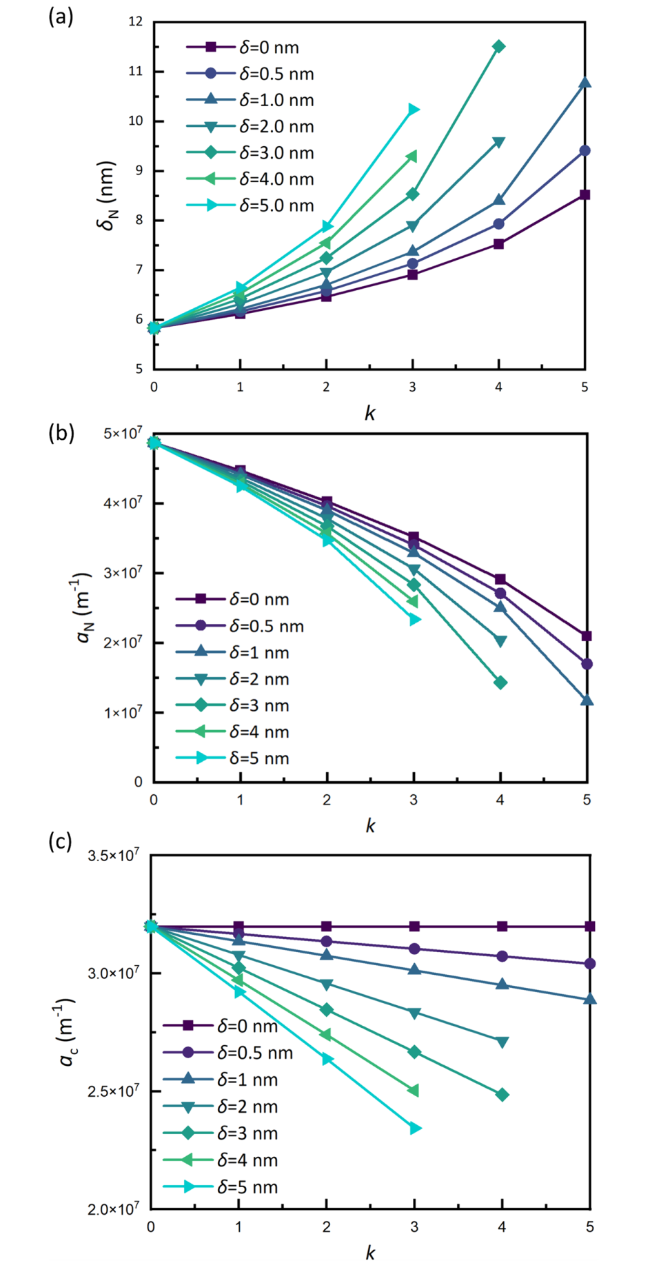

Fig. 2 Effects of contact and overlap of carbon particles on key structural parameters. (a) Ionomer film thickness δN. (b) Specific surface area of ionomer aN. (c) Specific surface area of carbon ac |

| Variables | Symbols | Values |

|---|---|---|

| Carbon radius | rc | 25 nm |

| Carbon density | ρc | 1.8 g cm-3 |

| Nafion density | ρN | 2.0 g cm-3 |

| Pt density | ρPt | 21.45 g cm-3 |

| Catalyst layer thickness | δCL | 10 μm |

| Electrochemical surface area | ECSA | 70 m2 g-1 |

| Porosity | εp | 0.5 |

| Henry’s constant | HN | 2.21×104 Pa m3 mol-1 |

| Ionomer-Pt interfacial coefficient | ζ | 0.8 |

| Temperature | T | 333.15 K |

| Oxygen diffusivity in ionomer | DN | 1×10-10 m2 s-1 |

2.3 Local oxygen reactive transport model

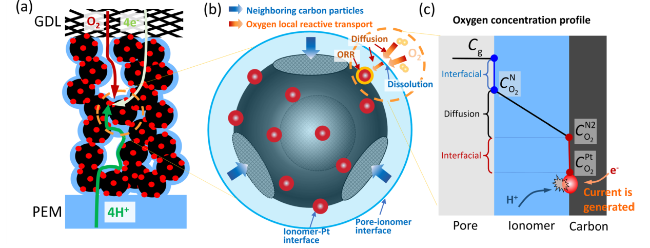

Fig. 3 Schematic of oxygen reactive transport processes in CLs. (a) Oxygen transport processes in the entire CLs. (b) Local oxygen reactive transport around a carbon particle with overlap considered. (c) Oxygen concentration profile across the ionomer film covered on Pt particles |

3 Model validation

3.1 Validation of local transport resistance

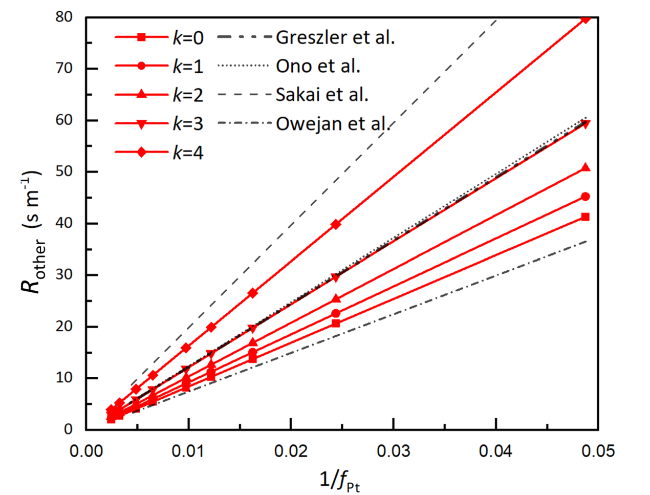

Fig. 4 Relationship between oxygen transport resistance and the reverse of Pt roughness |

3.2 Validation at the single cell-scale

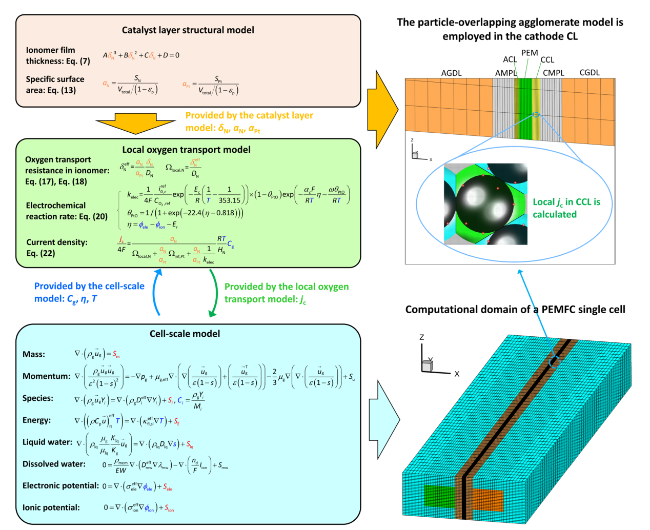

Fig. 5 Schematic of the coupling scheme between particle-overlapping model and cell-scale models |

| Parameters | Value |

|---|---|

| CCL thickness | 11 μm |

| ACL thickness | 6 μm |

| PEM thickness | 18 μm |

| GDLs thickness | 160 μm |

| GC length/width/height | 10.0 mm/0.5 mm/0.7 mm |

| Land width | 0.5 mm |

| Thermal conductivity of PEM | 0.77+3.7e-3λ |

| Thermal conductivity of CL | 0.27+0.66𝑠εCL |

| Thermal conductivity of MPL | In-plane: 0.15+0.66𝑠εMPL Through-plane:3+0.66𝑠εMPL |

| Thermal conductivity of GDL | In-plane: 1.7+0.66𝑠εGDL Through-plane:21+0.66𝑠εGDL |

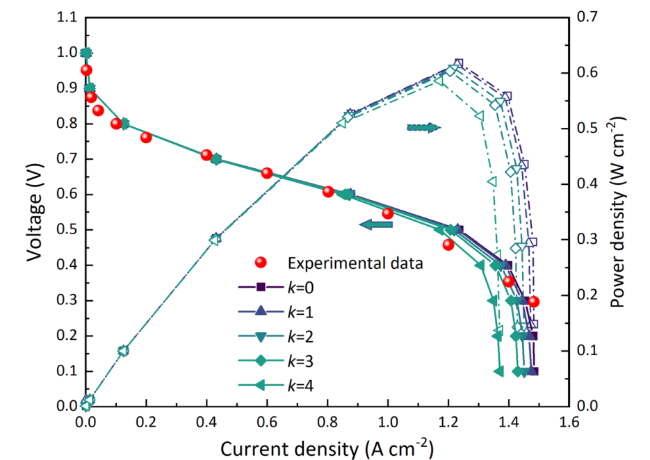

Fig. 6 Effects of carbon particle overlapping on cell performance |

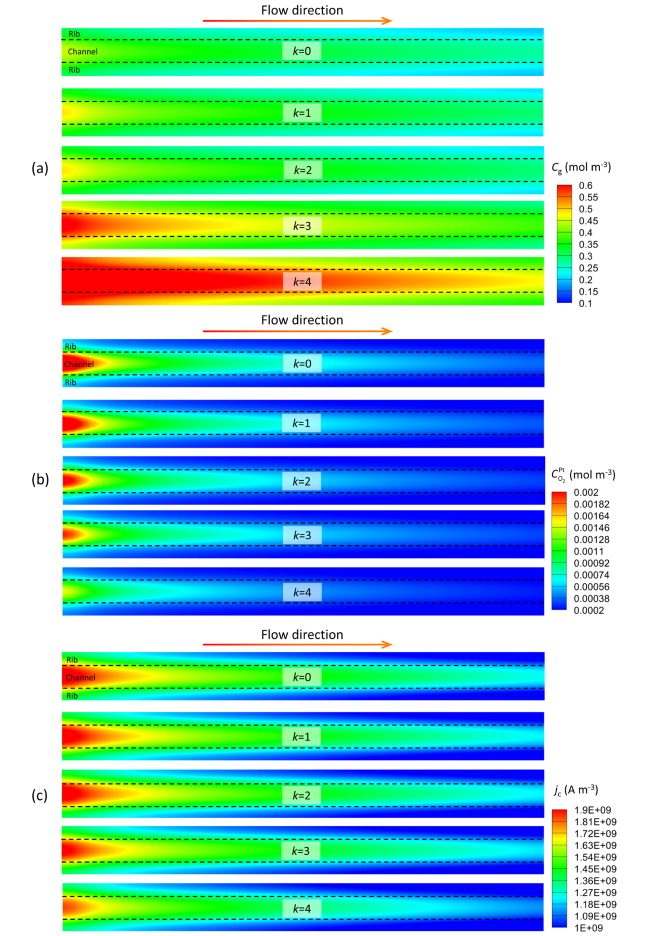

Fig. 7 Distributions of oxygen concentration and current density (0.1V). (a) Oxygen concentration in pores Cg, (b) oxygen concentration at Pt surface $C_{{{\text{O}}_{2} }}^{{{\text{Pt}}}}$ and (c) volumetric current density jc in the middle plane of the cathode CL |

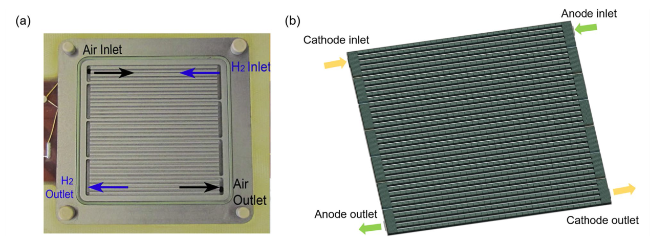

3.3 Validating at the commercial-size scale

Fig. 8 A commercial-size PEMFC with size of 7.1×7.1 cm2. (a) Bipolar plate with flow field in study of Los Alamos National Laboratory [60]. (b) Computational domain in this study |

Table 3 Structural parameters and operating conditions of the commercial-size PEMFC [60] |

| Parameters | Value |

|---|---|

| MEA area | 7.1×7.1 cm2 |

| CCL thickness | 12 μm |

| ACL thickness | 7 μm |

| PEM thickness | 18 μm |

| GDLs thickness | 200 μm |

| GC width/height | 1 mm/1 mm |

| Land width | 1.03 mm |

| Manifold width | 3 mm |

| Total bipolar plate thickness | 3 mm |

| Stoichiometry ratio | Anode: 1.2/Cathode: 2.0 |

| Porosity of GDL/MPL/CL | 0.6/0.4/0.4 |

| Pt loading in CCL | 0.4 mg cm-2 |

| I/C | 0.8 |

| Back pressure | 275.84 kPa |

| Relative humidity | 25%, 50%, 75%, 100% |

| Temperature | 353.15 K |

| Current density | 0.1, 0.4, 0.8, 1.0, 1.2 A cm-2 |

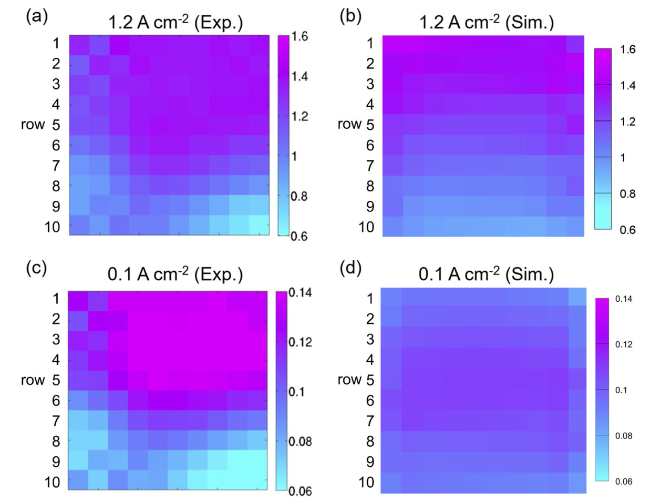

Fig. 9 Distribution of local current density under (a-b) 1.2 A cm-2, and (c-d) 0.1 A cm-2 (50% RH). The experimental results are from Ref. [60] |

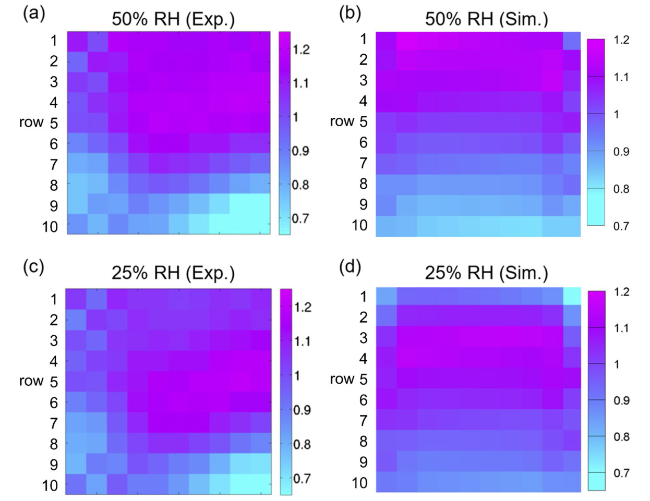

Fig. 10 Distribution of local current density under (a-b) 50% RH, and (c-d) 25% RH (1.0 A cm-2). The experimental results are from Ref. [60] |

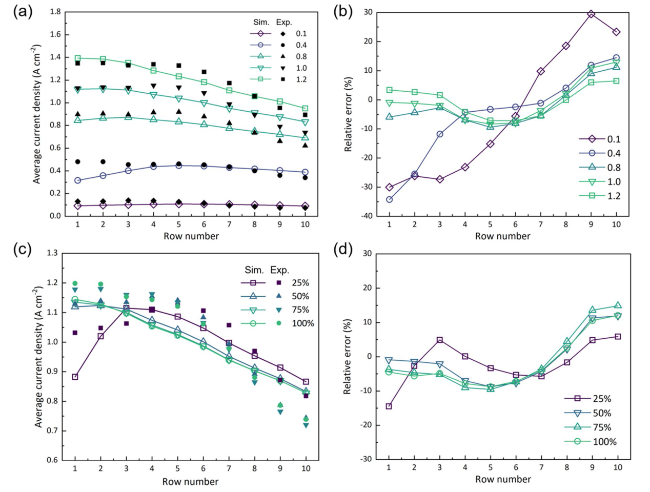

Fig. 11 Comparison between simulation and experimental results [60]. Distribution of average current density of each row under different (a) output current density and (c) RH. (b, d) Relative error between experimental and simulation results |

4 Results and discussion

4.1 Effects of Pt loading

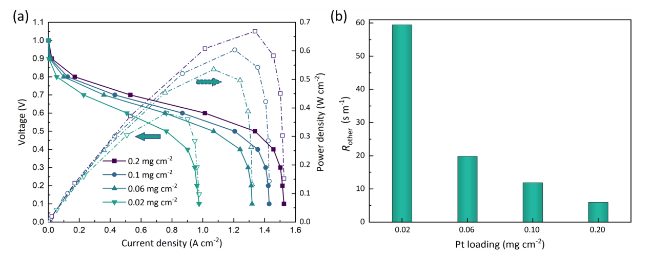

Fig. 12 Effects of Pt loading on cell performance. (a) Polarization curves and power density curves. (b) Oxygen transport resistance Rother |

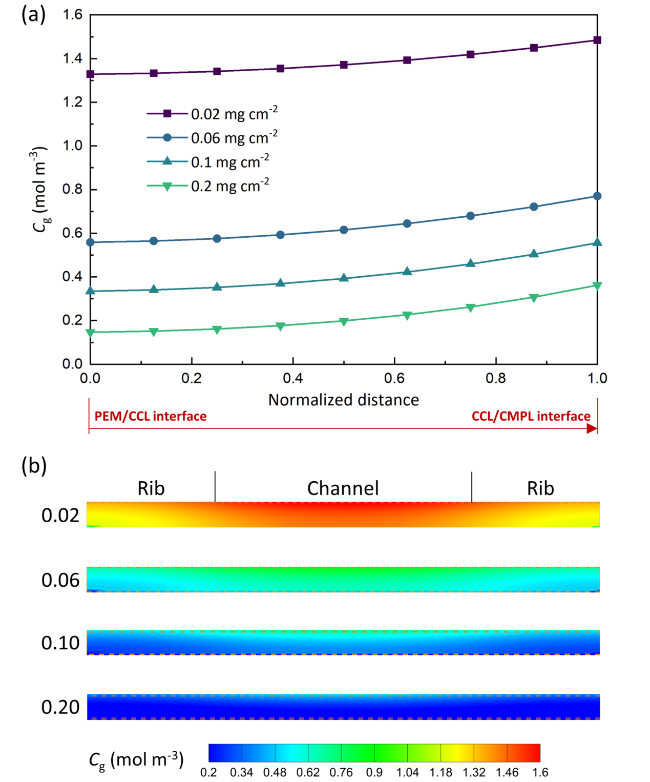

Fig. 13 Effects of Pt loading on oxygen concentration in pores Cg in the cathode CL (0.1 V). (a) Through-plane distribution of Cg. (b) Distribution of Cg on the center section of cathode CL perpendicular to the flow direction |

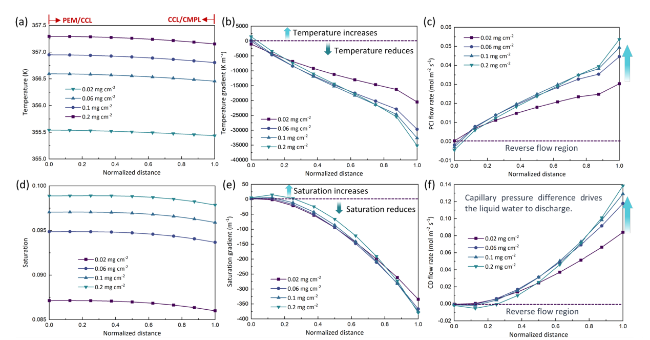

Fig. 14 Effects of Pt loading on PCI flow and CD flow in the cathode CL. Distributions of critical quantities are plotted, including (a) temperature, (b) temperature gradient, (c) PCI flow rate, (d) saturation, (e) saturation gradient, (f) CD flow rate |

4.2 Effects of I/C

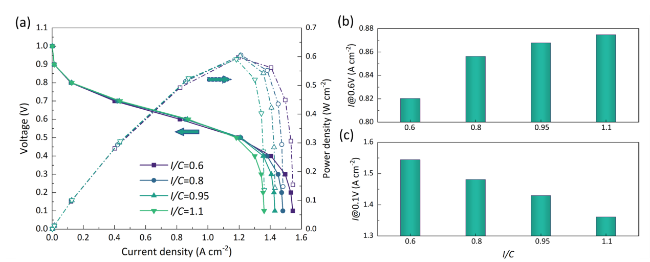

Fig. 15 Effects of I/C on cell performance. (a) Polarization curves and power density curves. (b) Current density at voltage of 0.6V. (c) Current density at voltage of 0.1V |

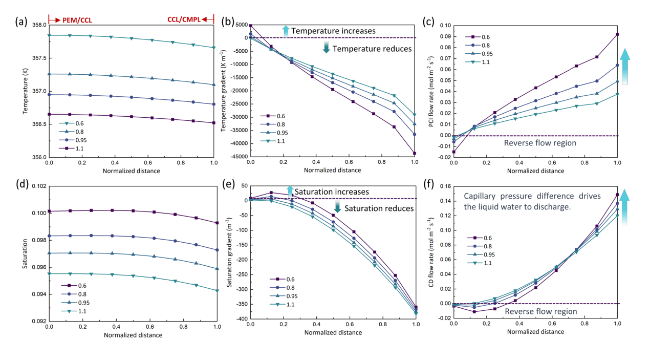

Fig. 16 Effects of I/C on PCI flow and CD flow in the cathode CL. Distributions of critical quantities are plotted, including (a) temperature, (b) temperature gradient, (c) PCI flow rate, (d) saturation, (e) saturation gradient, (f) CD flow rate |

4.3 Effects of ionomer partial coverage

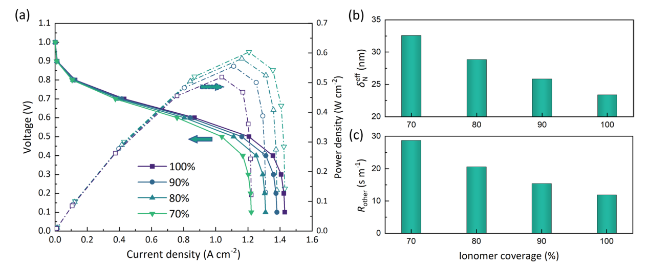

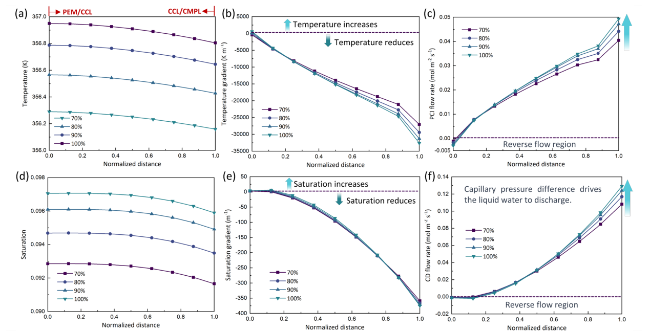

Fig. 17 Effects of ionomer coverage on cell performance. (a) Polarization curves and power density curves. (b) Effective oxygen transport length $\delta_{\mathrm N}^{\mathrm{eff}}$. (c) Oxygen transport resistance Rother |

Fig. 18 Effects of ionomer coverage on PCI flow and CD flow in the cathode CL. Distributions of critical quantities are plotted, including (a) temperature, (b) temperature gradient, (c) PCI flow rate, (d) saturation, (e) saturation gradient, (f) CD flow rate |

4.4 Effects of carbon particle radius

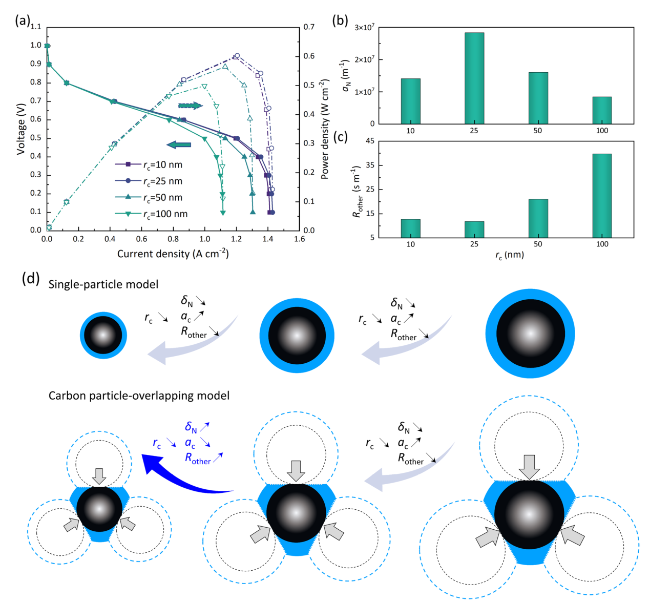

Fig. 19 Effects of carbon particle radius on cell performance. (a) Polarization curves and power density curves. (b) Specific surface area of ionomer aN. (c) Oxygen transport resistance Rother. (d) Schematic of variation of structural parameters and ionomer distribution in the single-particle model and the particle-overlapping model |

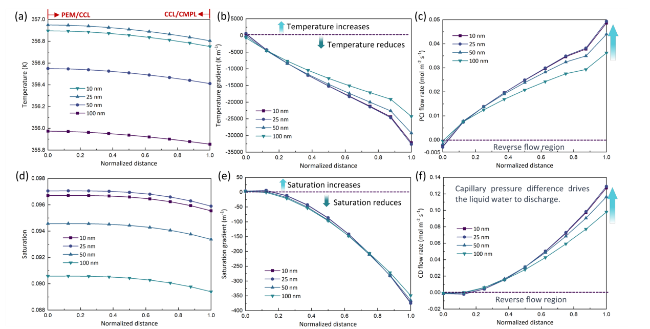

Fig. 20 Effects of carbon particle radius on PCI flow and CD flow in the cathode CL. Distributions of critical quantities are plotted, including (a) temperature, (b) temperature gradient, (c) PCI flow rate, (d) saturation, (e) saturation gradient, (f) CD flow rate |