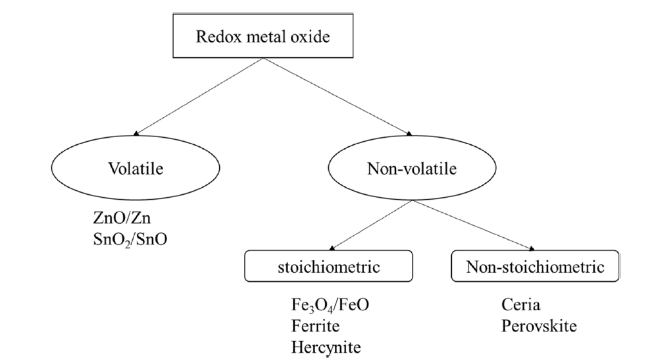

Although the cycle is volatile at 1 bar [

179,

188], it becomes non-volatile at 1700 K under an inert atmosphere, e.g., under nitrogen gas flow. However, it requires another large energy input, e.g., pumping power for the inert sweeping gas. The PROMES group experimentally investigated the performance of the cycle under nitrogen gas flow at 0.1 bar with a solar furnace [

32]. They found that the conversion of the reduction can reach 100%, while the oxidation kinetics is limited by the coagulation due to alternating fusion and solidification of FeO within the cycle. As a result, a granulation is needed in the continuous process, even though it is hard to be implemented. The mixed solid solutions of Fe

3O

4/FeO and M

3O

4/MO (ferrites) can further reduce the reduction temperature [

102]. Lots of ferrites with lower reduction temperatures have been investigated, which are listed in

Table 3. Based on the theoretical thermodynamic analysis [

15], the stabilities of M-ferrite follows the rank of Fe

3O

4 > CoFe

2O

4 ∼ NiFe

2O

4 > ZnFe

2O

4. Moreover, Fresno et al. [

60,

61] experimentally evaluated the activity of commercially available ferrites with different compositions, NiFe

2O

4, Ni

0.5Zn

0.5Fe

2O

4, ZnFe

2O

4, Cu

0.5Zn

0.5Fe

2O

4 and CuFe

2O

4. The net hydrogen production and cyclability after the first reduction-oxidation cycle decreases in the order NiFe

2O

4 > Ni

0.5Zn

0.5Fe

2O

4 > ZnFe

2O

4 > Cu

0.5Zn

0.5Fe

2O

4 > CuFe

2O

4. Among the ferrites in

Table 3, Ni

0.5Mn

0.5Fe

2O

4 has the lowest reduction temperature, while the cyclability is unfeasible. NiFe

2O

4/m-ZrO

2 has the highest hydrogen production rate [

60,

61,

79]. ZnFe

2O

4 is least desirable because of the high temperature for the reduction.