1 Introduction

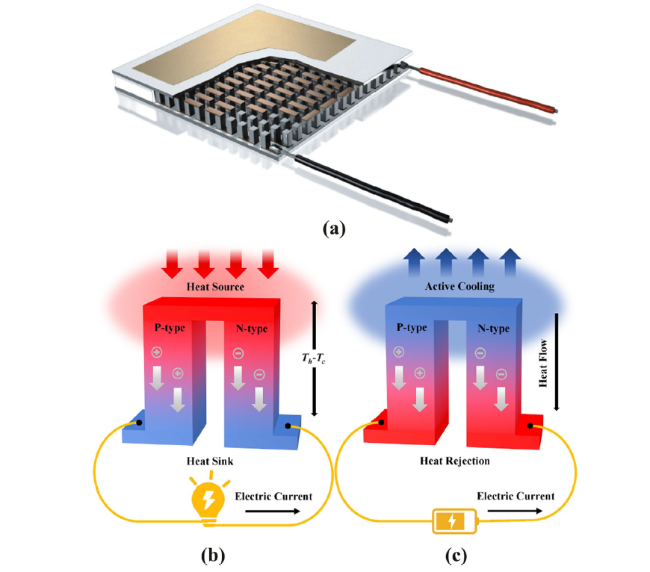

Fig. 1 a Illustration of TE device (http://www.ferrotec.com.cn/en/products/productinfo/84.html); Mechanisms of b Seebeck effect and c Peltier effect |

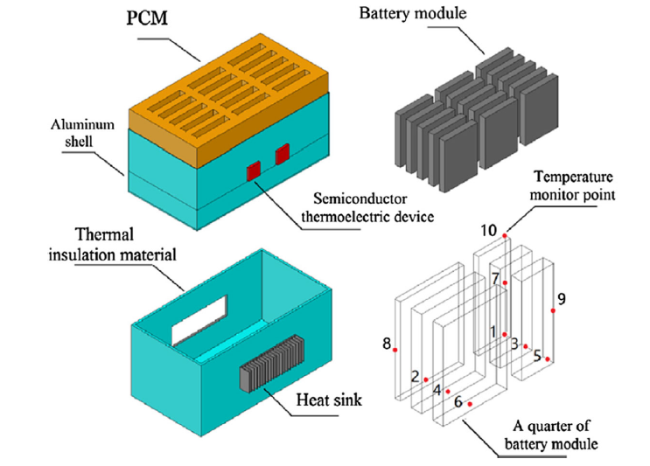

2 Configuration types and characteristics

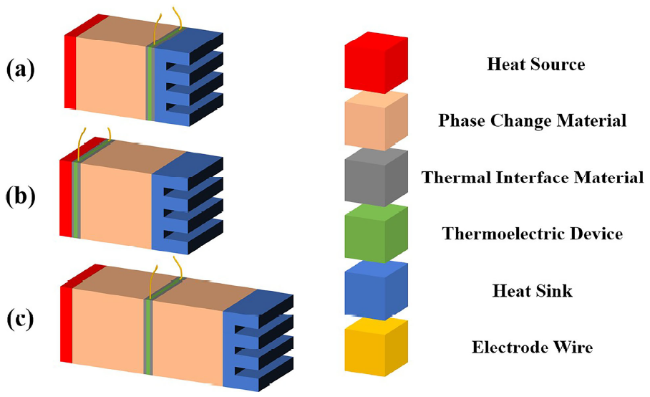

Fig. 2 Schematic diagram of the structure in three configuration types of TE-PCM system: a PCM/TE, b TE/PCM, c PCM/TE/PCM |

Table 1 Main advantages and disadvantages of three configuration types for TE-PCM systems |

| Configuration type | Advantage | Disadvantage |

|---|---|---|

| PCM/TE | • High temperature waste heat recovery • No interference from reverse current • Sensitive thermal response | • High cooling requirements |

| TE/PCM | • Low temperature waste heat recovery or temperature adjustment • Low cooling requirements and even only with PCM | • Having interference from reverse current |

| PCM/TE/PCM | • Waste heat recovery over a wide temperature range • Excellent total power generation | • Slow thermal response • Requiring a large difference in thermal properties of PCM |

2.1 PCM/TE

2.2 TE/PCM

2.3 PCM/TE/PCM

3 Application development

3.1 TEG-PCM

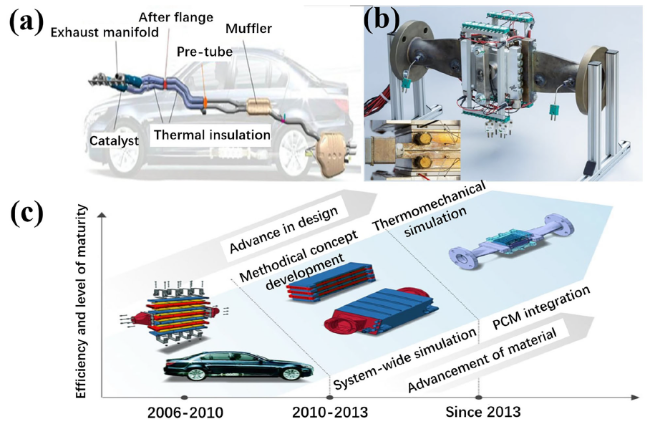

3.1.1 Traffic

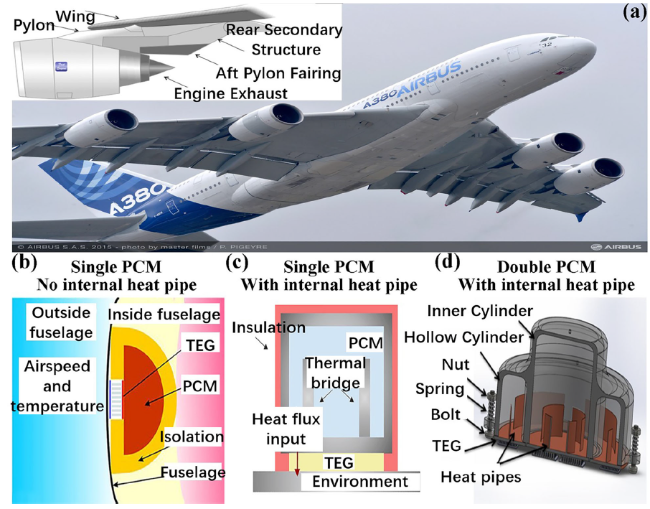

Fig. 4 Thermoelectric energy harvesting in aircraft: a Aft pylon fairing and a possible installation area where the TEG can be placed [74]; Schematic diagram and assembled device image of TEGs integrated with b single PCM (without internal heat pipe) [75], c single PCM (with internal heat pipe) [76,77], d double PCM (with internal heat pipe) [78] |

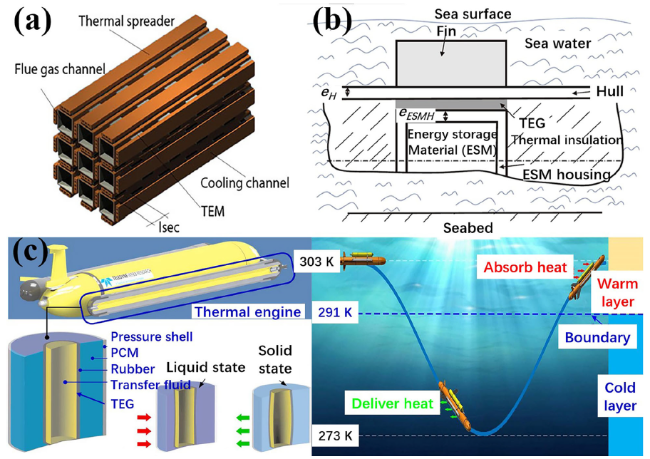

Fig. 5 Thermoelectric energy retrieval of vessel, underwater glider and unmanned underwater vehicle (UUV) in ocean: a Design of TEG with modular cross-section for installation in the flue from a waste incinerator onboard [82]; b Schematic diagram of a TEG-PCM system embedded in the hull of an underwater glider [84], and potential system arrangement inside hull; c Conceptual design of a double-layer structure oceanic thermal engine of UUV and schematic representation of ocean thermal energy conversion throughout its ascent and descent [85,86] |

3.1.2 PV-TEG-PCM

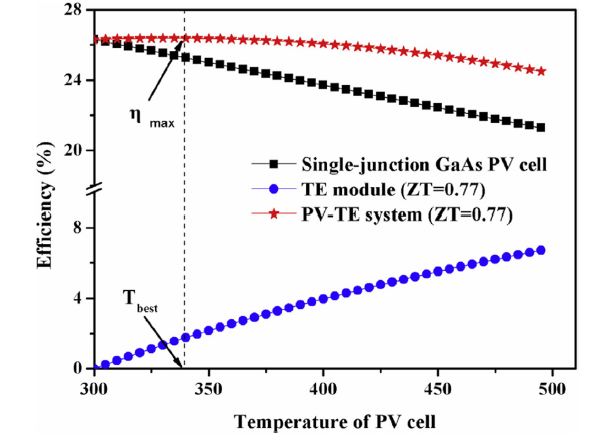

Fig. 6 Efficiency of PV-TEG system corresponding to different working temperatures [108] |

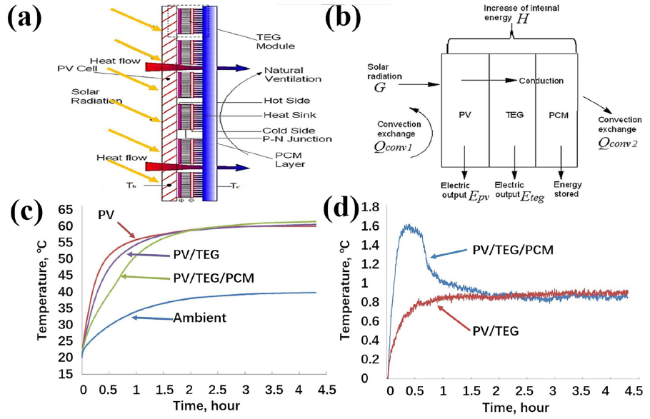

Fig. 7 a Physical arrangement and b energy pathway of the PV/TEG/PCM system; c PV cell back temperature profiles of standard PV, PV-TEG and PV/TEG/PCM system; d Temperature difference across hot and cold sides of the TEG for PV-TEG and PV/TEG/PCM system [109] |

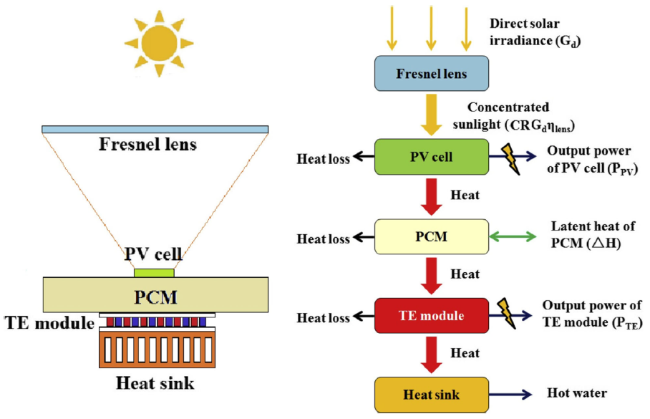

Fig. 8 Schematic illustrations of the structure and the energy flow of PV/PCM/TEG hybrid system [117] |

3.1.3 ST-TEG-PCM

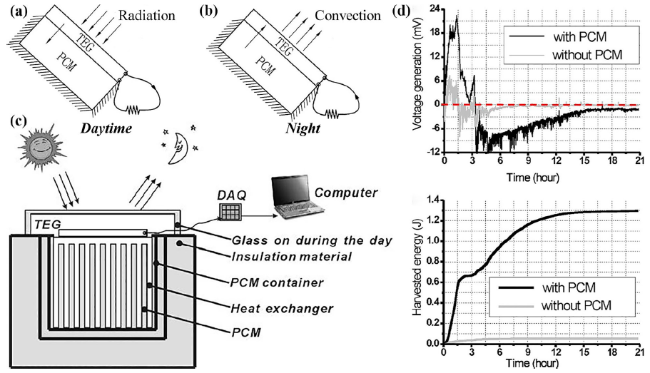

Fig. 9 Sketch drawings of the energy harvesting idea: a solar radiation on the TEG during the day and b PCM work as the heat source at night, c diagram of the prototype work unit in the outdoor experiment, d comparison of voltage generation and harvested energy in actual solar radiation between work units with and without PCM [139,140] |

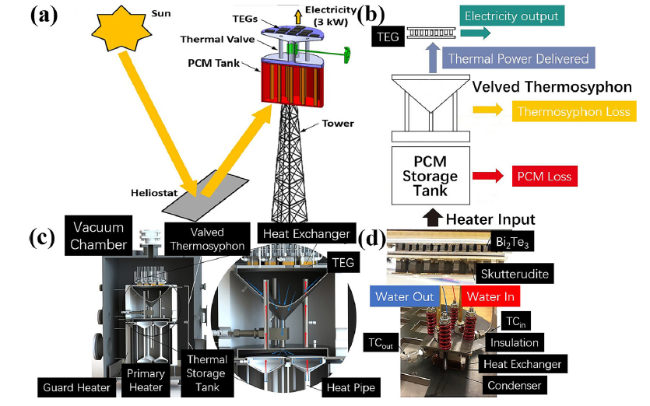

Fig. 10 a Schematic diagram and b working mechanism of the proposed ST/PCM/TEG power station with dispatchable heat storage and thermal valve, c internal structure sectional view of the thermosyphon-based thermal valve used for controlling high-temperature heat flow from PCM to TEG, d the cascaded TEG consisting of two types of TEGs: Skutterudite TEG on the hot side and Bi2Te3 TEG on the cold side (TIM is used for enhancing the heat transfer between two TEGs) [154,155] |

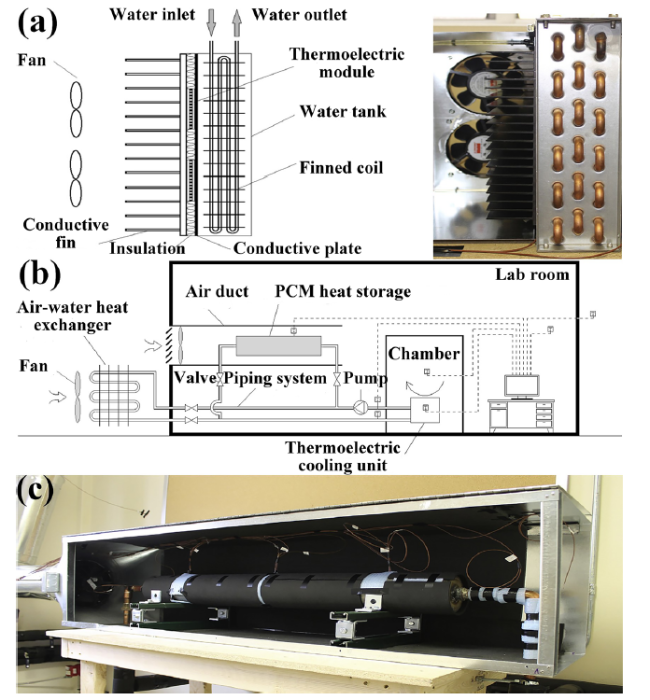

3.2 TEC-PCM

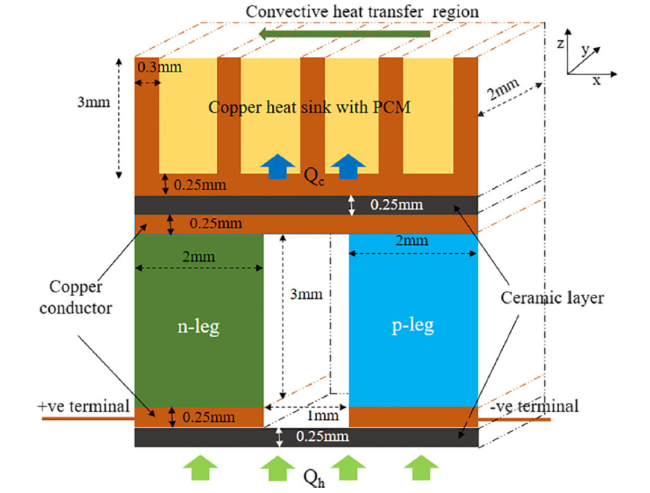

Fig. 11 Schematic representation of TEC integrated with PCM-based heat sink [46] |

Fig. 13 Schematic diagram of the standby battery pack with TEC and PCM for outdoor base station [160] |

4 Design optimization

4.1 PCM

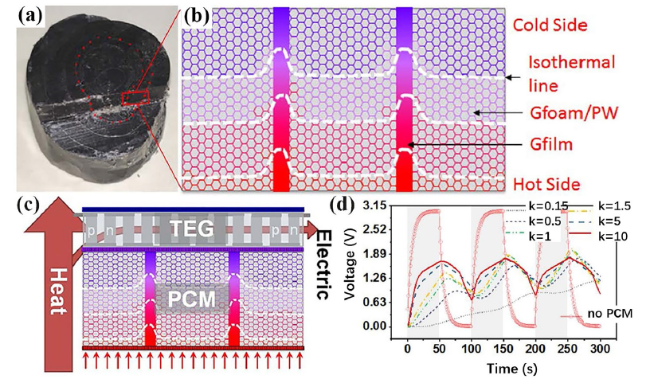

Fig. 14 Gfilm/Gfoam/PW: a structure of composite PCM sample, b heat conduction mechanism, c schematic diagram of TEG system with composite PCM, d open circuit voltage variations of the TEG with PCMs that have different thermal conductivities in the fluctuating thermal environment [167] |

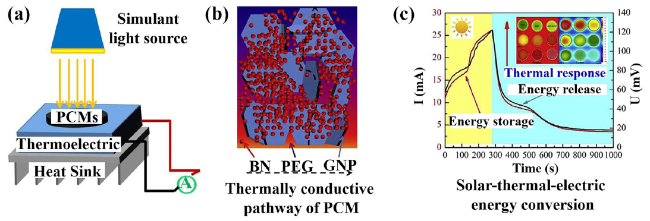

Fig. 15 a Experimental setup of a TEG with composite PCM for solar-thermal-electric energy conversion, b thermally conductive pathway of PEG/BN/GNP composite PCM, c I-t and U-t curves of the TEG with composite PCMs under simulant sunlight radiation (at 400 mW/cm2) on/off [169] |

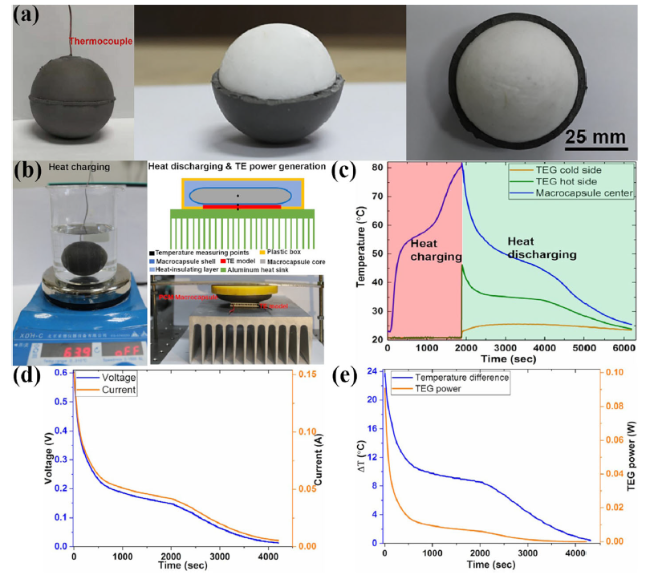

Fig. 16 a Optical photos of the PCM macrocapsule that consists of octadecanol core and silicone elastomer shell, b heat charging and discharging of the PCM macrocapsule used for TEG, c temperature profiles of PCM macrocapsule and two sides of TEG, d output voltage, electric current and e output power, temperature difference on both sides of TEG versus time [170] |

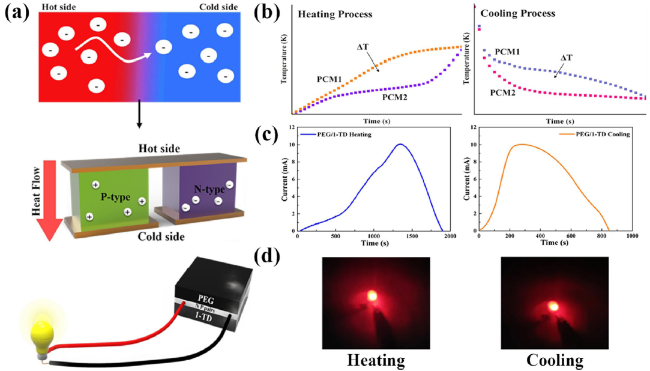

Fig. 17 a Schematic illustration of the thermoelectric energy harvesting system with two PCMs involved PEG and 1-TD embedded with porous graphene aerogel during heating and cooling process: b temperature profiles of PCMs, c electric current variations of TEG, d red LED light turned on using the harvested electrical energy [47] |

4.2 TE device

4.3 Structure

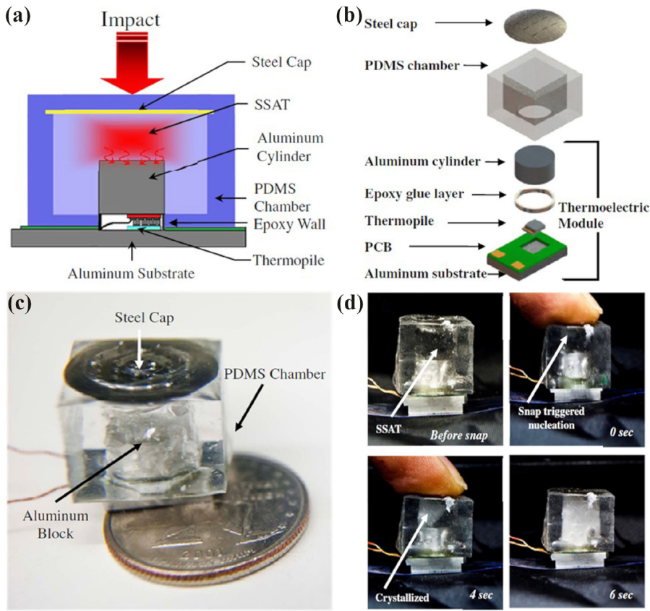

Fig. 18 Impact triggered TEG: a basic structure, b exploded view of the device showing various components, c photograph of the device with PDMS chamber, d snapshots of sodium acetate trihydrate crystallization process after impact trigger [181] |

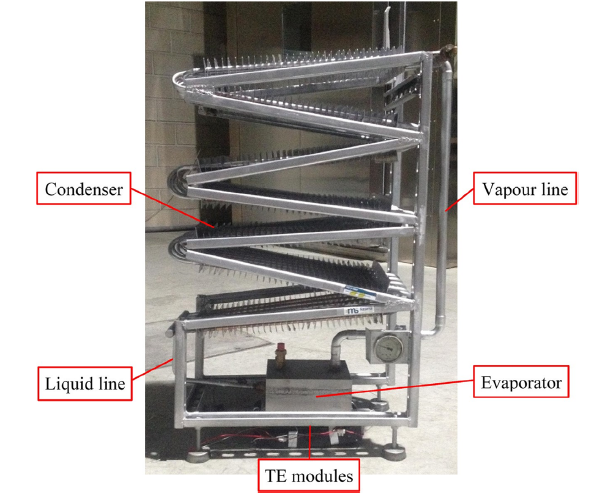

Fig. 19 Prototype of a TEG system using thermosyphon with phase change as heat exchanger [182] |

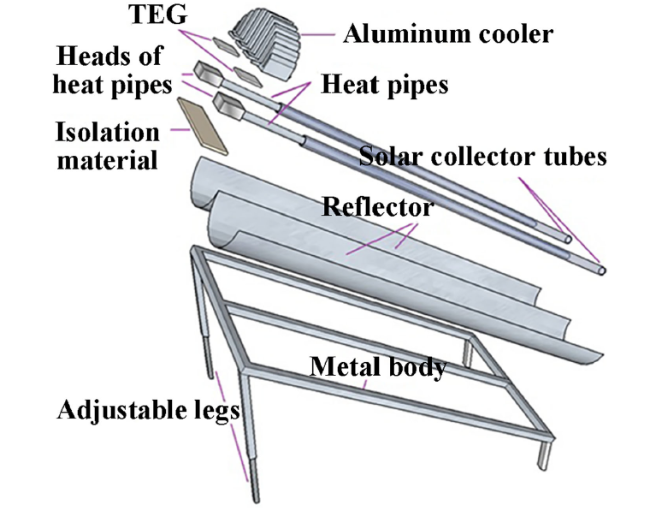

Fig. 20 Physical structure of a TEG system with two-phase thermosyphon heat pipes and nanofluids [183] |

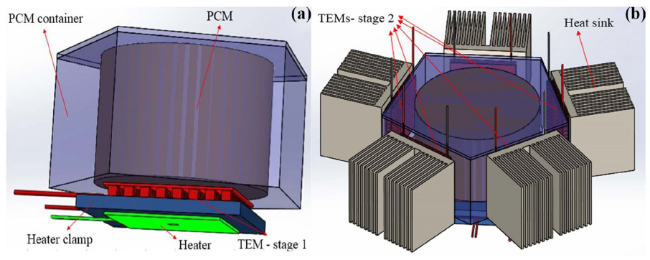

Fig. 21 Schematic diagram of two-stage TEG system: a TEG and heat source in stage 1, b TEGs and heat sinks in stage 2 [184] |

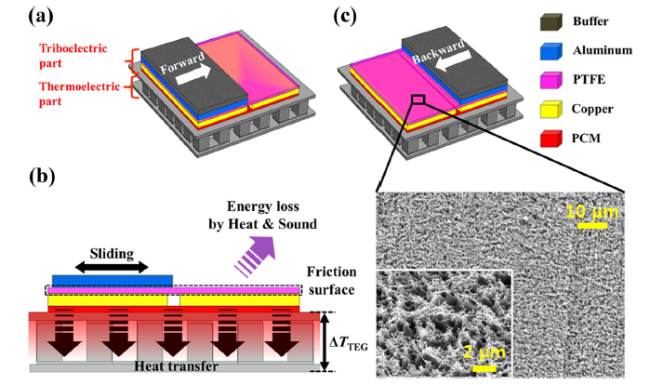

Fig. 22 a Proposed hybrid nanogenerator, b detailed illustration of the working mechanism of the hybrid nanogenerator, c FESEM image of the nanostructured PTFE surface [186] |

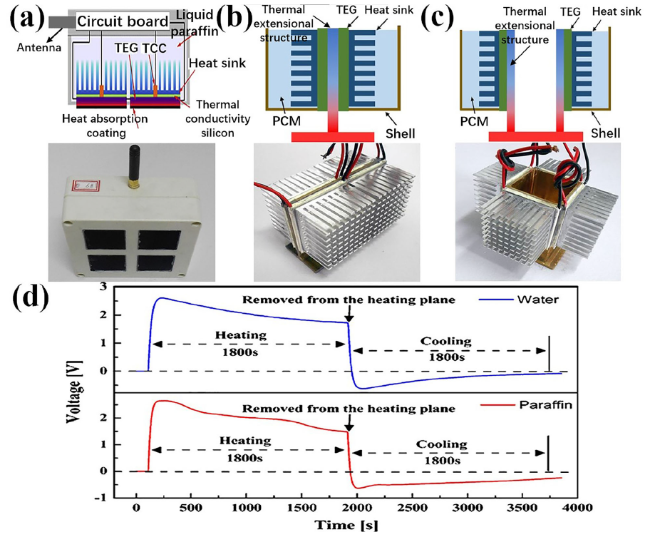

Fig. 23 Cross-sectional schematic diagram and photograph of a SPWTS that consists of TEG and PCM-integrated heat sink, three arrangement types of heatsink with a 2D plane parallel structure, b 3D filling thermal extensional structure c 3D hollow thermal extensional structure; d comparison of voltage profile in TEG using heat sink with integration of water or paraffin [187,188] |

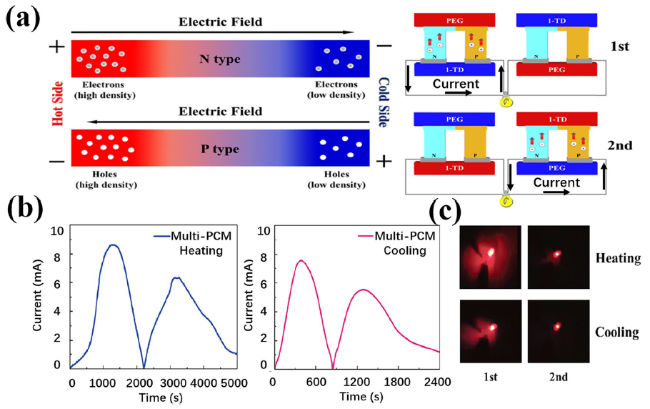

Fig. 24 a Schematic illustrations of the multiple energy harvesting system composed of two pairs of PEG and 1-TD PCM couples and two TEGs, b electric current profiles during heating and cooling processes, c images of red LED bulb lit by using the harvested electric energy [189] |

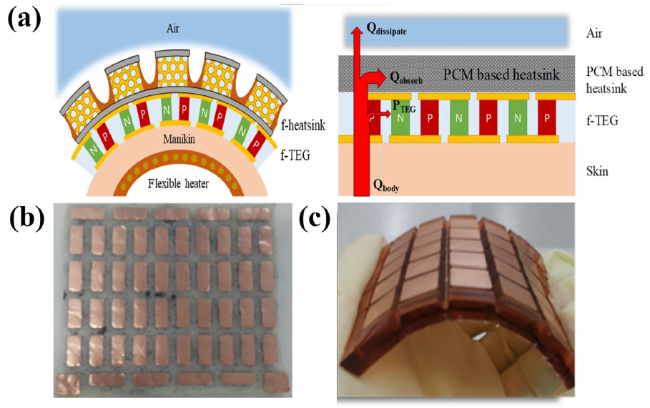

Fig. 25 a Schematic diagram and working mechanism of a flexible TEG with PCM-based heatsink, b photograph of flexible TEG, c structure design of PCM-based flexible heatsink [190] |