However, CCS projects are facing a number of challenges. For example, the technology is not yet cost-effective on the industrial scale and deemed to be unreliable by doubters [

10]. In fact, one of the important CCS projects was behind schedule by 2021 and Chevron admitted it broke restrictions imposed by regulators to get its $54 billion Gorgon Liquid Natural Gas (LNG) processing center approved by Australia. Others argue the trouble stems from the large power consumption of CCS facilities making themselves significant carbon emitters. A coal power plant with carbon capture facilities would need 25% more electricity and after separation, an unknown amount of carbon dioxide is emitted to the atmosphere. When considering the additional energy demand and potential leakage downstream, there is no strong evidence that all the CO

2 can be captured. Furthermore, there is disagreement about the utility of CCS and associated concepts like carbon capture, utilization, and storage (CCUS) [

11,

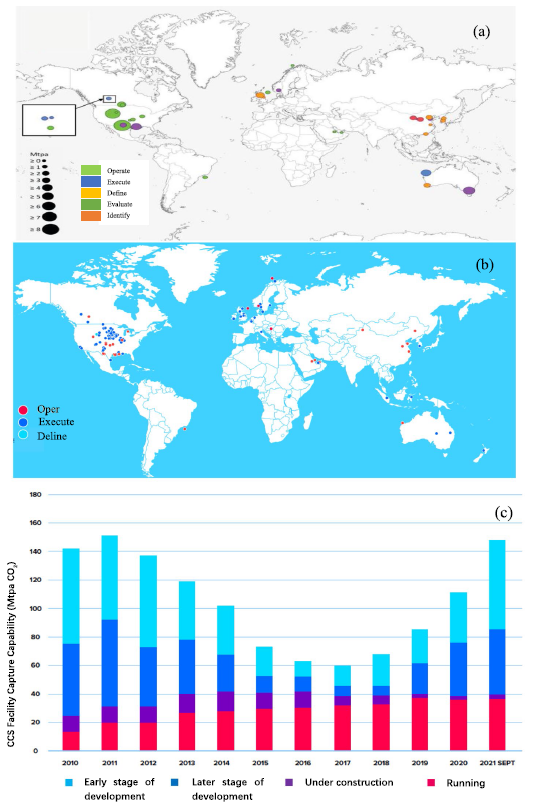

12]. Two members of the Global Carbon Absorb and Storage Institute assessed 26 CCS facilities around the world in 2021 and concluded that the technology had been implement on a scale to safely capture and store carbon dioxide. However, in a review comprising 39 CCS programs in the United States, researchers have arrived at a different conclusion. The CCS project development has a poor track record [

13] and the fact that the oil and gas industry frequently recommends as a critical carbon reduction option does not bode well for the technology. One of the few applications where CCS seems to have unquestioned success is enhanced oil recovery in which carbon dioxide is injected into a well to help extract more fossil fuel, but this is not a good way to reduce climate change [

14]. Meanwhile, in the power sector, the capture rate is almost zero and even the International Energy Agency which is long seen as a booster to the oil and gas industry casts doubts on the large-scale viability of CCS [

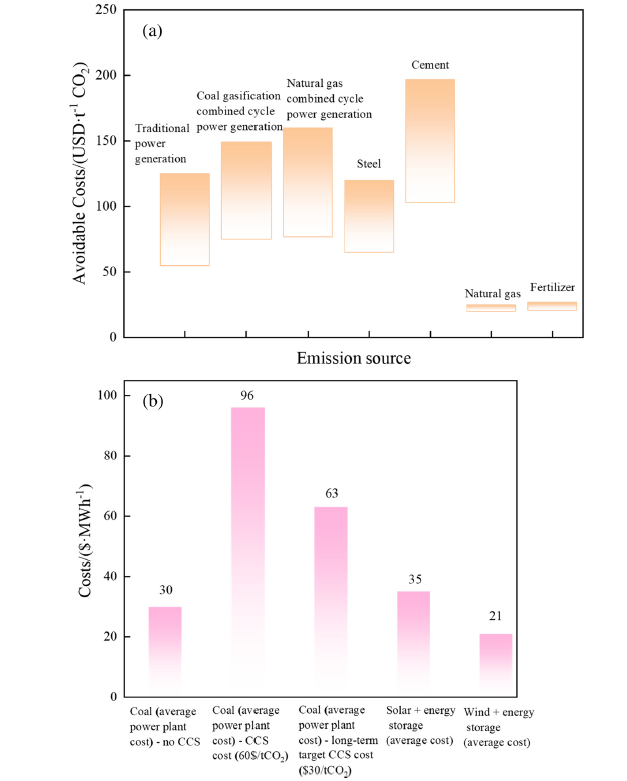

15]. Globally, owing to the economical constraints and lack of profitable sources, CCS development is in a bad state and far below the scale proposed by the IEA [

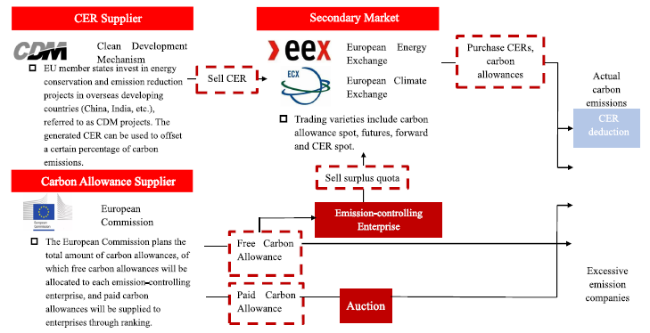

16]. To improve this situation, the economic value of CO

2 has been widely discussed, and the Carbon Sequestration Leadership Forum (CSLF) changed the term “CCS” to “CCUS” (Carbon Capture, Utilization, and Storage, CCUS) [

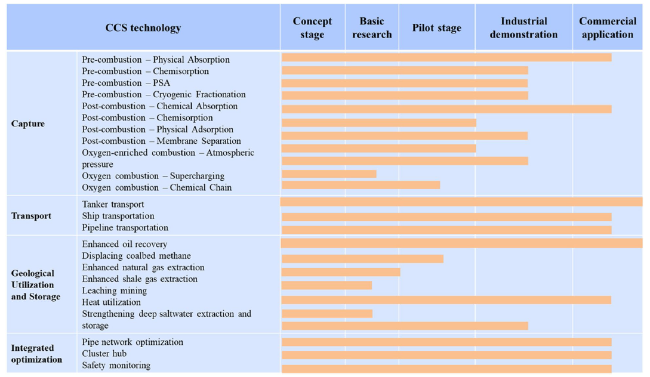

17]. CCUS technology is a technology that directly separates CO

2 from the emission source that produces CO

2, compresses, transports, and carries out geological storage or resource utilization. Among them, the carbon capture process is the part with the highest energy consumption and cost in the whole process, so the research on carbon capture technology is also the focus of CCUS technology development [

18,

19]. The CO

2 emission sources include stationary source emissions (including energy consumption emissions from power plants and other large industrial processes) and mobile CO

2 emissions (including transportation, etc.), of which stationary source emissions account for about 60%.

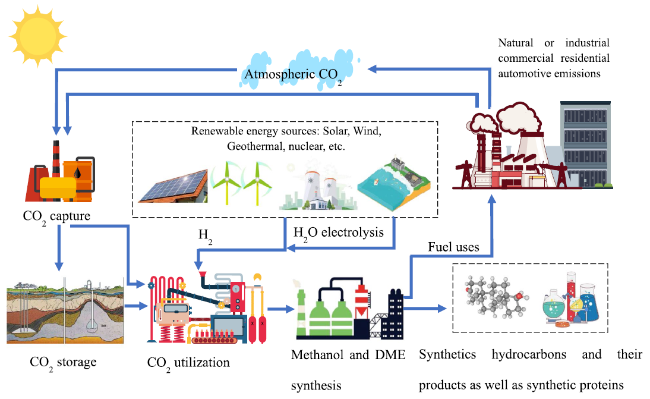

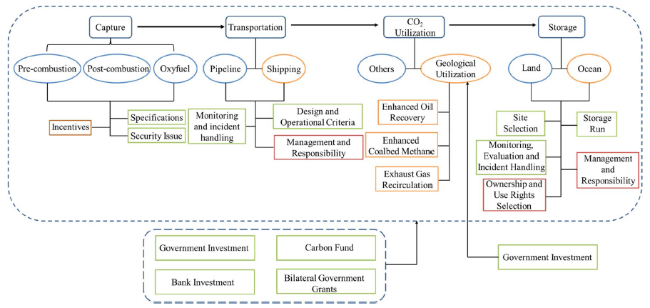

Figure 2 shows the main route of the current CCUS technology. But the net-zero emissions pathway proposed by the IEA envisages a smaller role for CCUS and CO

2 removal than the ambitious scenarios developed by the United Nations' Intergovernmental Panel on Climate Change.